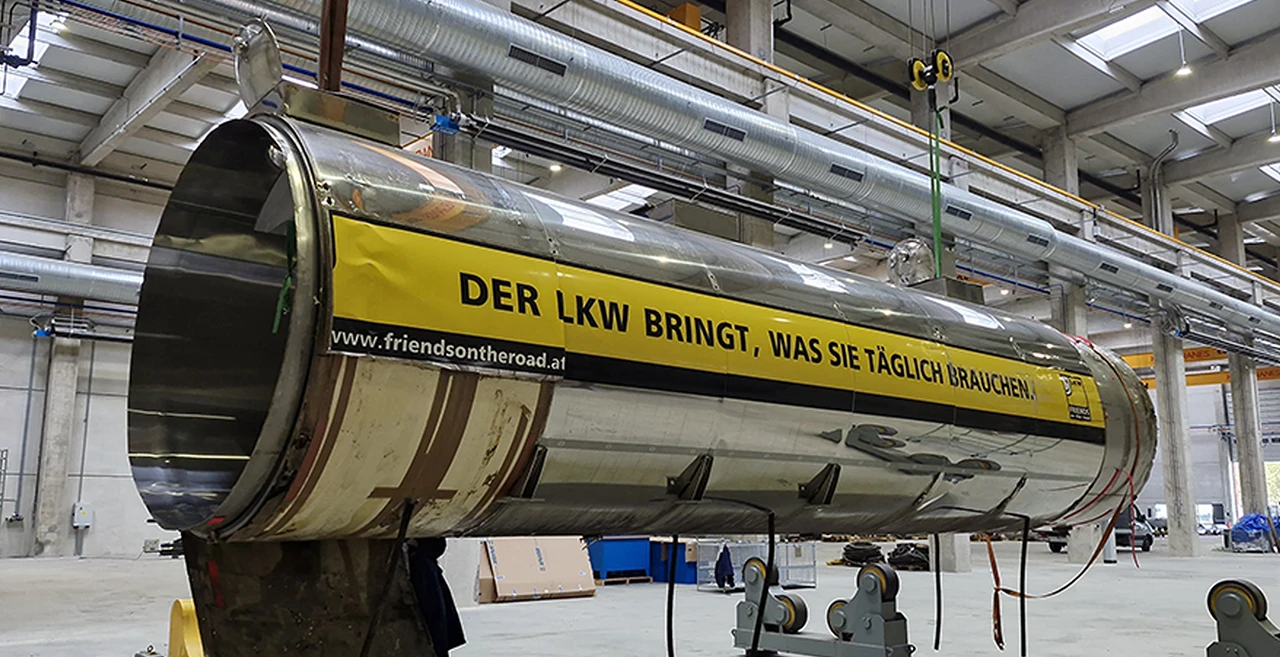

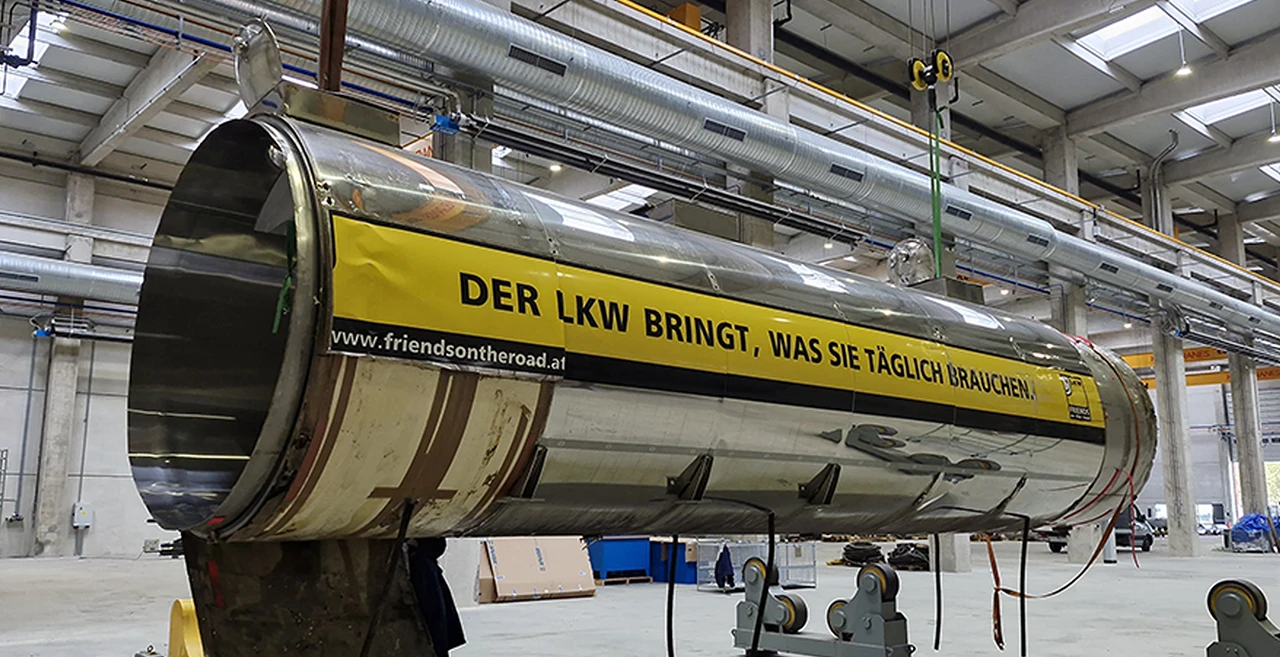

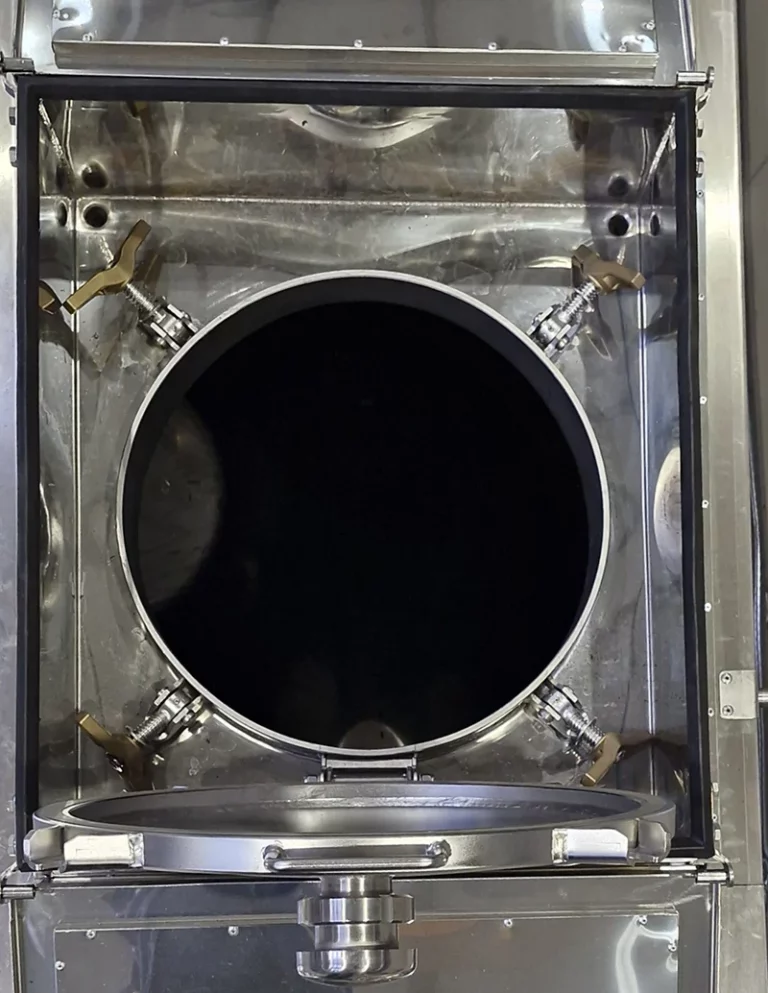

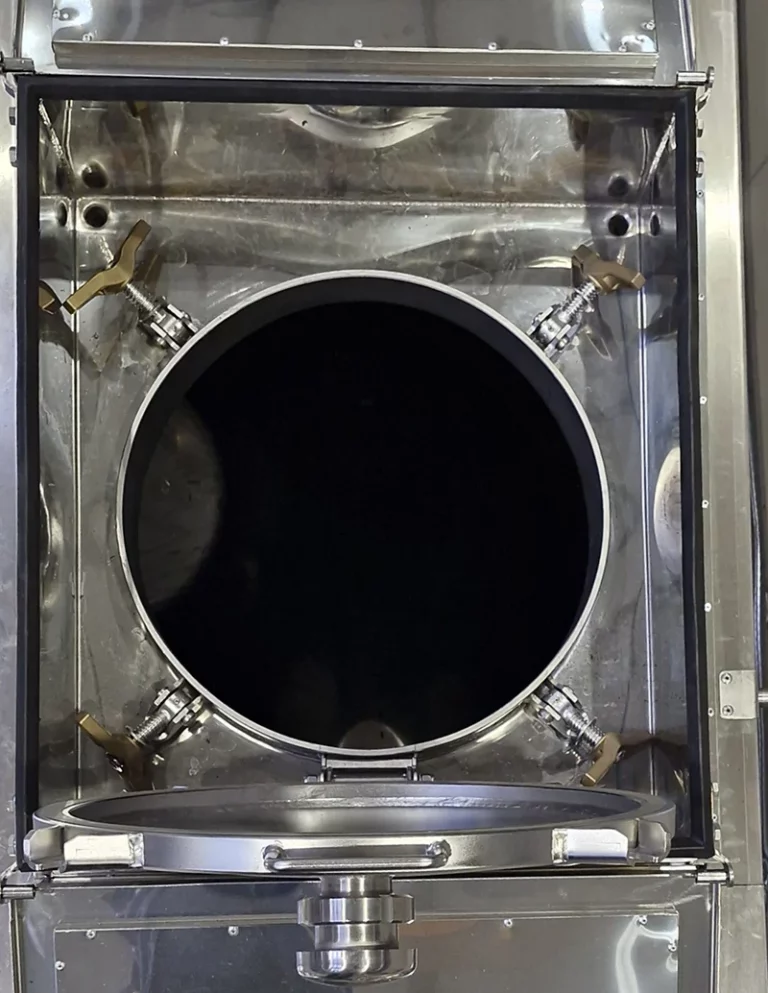

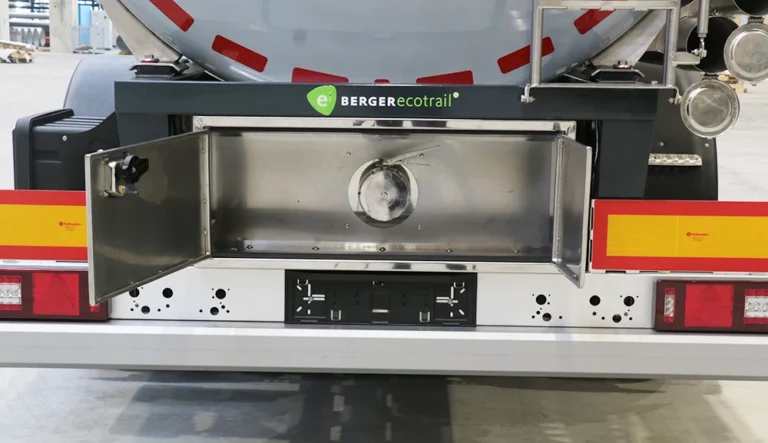

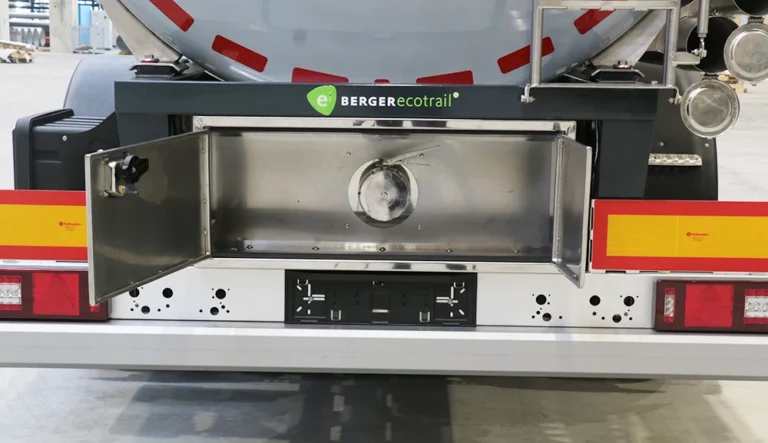

Letina offers a comprehensive range of high-quality semi-trailer tanks engineered for the safe, efficient, and reliable transport of diverse liquid goods. Our tanks are made with high-quality materials and precision engineering to meet the specific requirements of various industries.

We offer comprehensive repair and maintenance services for tankers, ensuring quality and efficiency for every intervention. Rely on our experienced staff for fast and efficient service.

Our goal is to ensure that your tankers are always in optimal condition. Trust in our expertise for seamless transport.

Address: Luna 1, 6250 Kundl

Phone: +43 5338 7500

Fax: +43 5338 8775

Email: nutzfahrzeuge@hochstaffl.com

Website: www.hochstaffl.com

Address: Bundesstraße 9, 7221 Marz

Phone: +43 2626 64461

Fax: +43 2626 64493

Email: nutzfahrzeuge@hochstaffl.com

Website: www.hochstaffl.com