We manufacture sanitary stainless steel tanks and processing equipment. In our expansive catalog you will find:

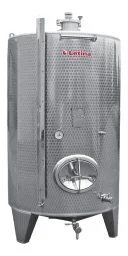

Letina stainless steel tanks are customizable in many different ways to fit into your production process seamlessly. Some of the features are stacking technology, custom tops and bottoms, various footing options and different cooling/heating jackets.

All of our equipment is constructed using only high-grade stainless steel materials (AISI 304 and 316L). Welds are made using the advanced TIG method, brushed and polished for extra protection. The stainless steel tanks are rigorously tested to make sure they live up to the Letina quality standards.

Clean-In-Place station is a device that automates the cleaning of winery and brewery equipment without disassembling it.

A mash tun heats malt and water to convert starches into sugars, creating wort. It also functions as a boil kettle, boiling wort with hops to enhance flavor and remove volatiles.

A lauter tun separates wort from grain using a slotted bottom and rake for efficient filtration. It improves clarity and consistency before boiling and fermentation.

A whirlpool tank spins wort to separate solids, enhancing clarity and quality. It ensures a cleaner wort before fermentation.

Thanks to the combination of the above featured properties,

stainless steel tanks have a tremendously high value-to-cost ratio.

Letina tanks are made of AISI 304 grade stainless steel. It offers the best properties for sanitary, food and beverage processing. For highly-corrosive environments, such as salty or acidic areas, tanks are manufactured out of the higher-grade AISI 316L stainless steel.

AISI 304 stainless steel is an austenitic metal, which means it has the following properties:

AISI 316L stainless steel has all of the benefits of its 304 sister metal, with a minor difference in structure.

The “L” in AISI 316L stands for “low” carbon content, resulting in a minor strength boost.

AISI 316L is “rich” in Molybdenum (Mo) which further increases its corrosion resistance, making it suitable for marine environments.

If your equipment is located in a salty or acidic environment, AISI 316L is a must.

At Letina we use only high-grade materials. Our standard tanks are manufactured out of AISI 304 stainless steel and there is an upgrade to AISI 316L stainless steel available for corrosive environments.

AISI 304 stainless steel is an austenitic metal, which means it has the following properties:

AISI 316L stainless steel has all of the benefits of its 304 sister metal, with a minor difference in structure.

The “L” in AISI 316L stands for “low” carbon content, resulting in a minor strength boost.

AISI 316L is “rich” in Molybdenum (Mo) which further increases its corrosion resistance, making it suitable for marine environments.

If your equipment is located in a salty or acidic environment, AISI 316L is a must.

When the surface of steel is exposed to oxygen, it forms ferric oxide (Fe2O3), which we know as rust. Layers peel off, reducing the structural integrity of the material and exposing more layers to oxygen, creating more rust.

Stainless steel, on the other hand, forms a layer of chromium oxide upon exposure with oxygen. It is a microscopic layer that acts as a force-field and prevents oxygen from reacting with the steel and forming rust.

Yes, stainless steel can rust.

Even if the surface of stainless steel is scratched, a protective chromium oxide layer will reform as long as there is sufficient chromium present. What causes stainless steel to rust are tiny particles of “normal” steel touching the stainless steel surface. This allows the rust to avoid the protective layer of chromium oxide and spread beneath it.

The most common causes of rust in stainless steel tanks are the welds holding everything together. The best way to avoid it is to use TIG Welding. Here at Letina we go a step further, brushing and polishing the welds to make sure our stainless steel tanks have no weak spots.

Another common cause is stainless steel tanks getting contaminated by normal, non-stainless metals. Rust can spread by contact, which is why manufacturers mustn’t cut costs and use inferior parts on their tanks. Letina tanks use stainless steel components exclusively.

If you’re working in a corrosive environment, such as near salt-water or using corrosive chemicals, stainless steel can begin to rust. That is why in such environments AISI 316L stainless steel with superior corrosion resistance is used.