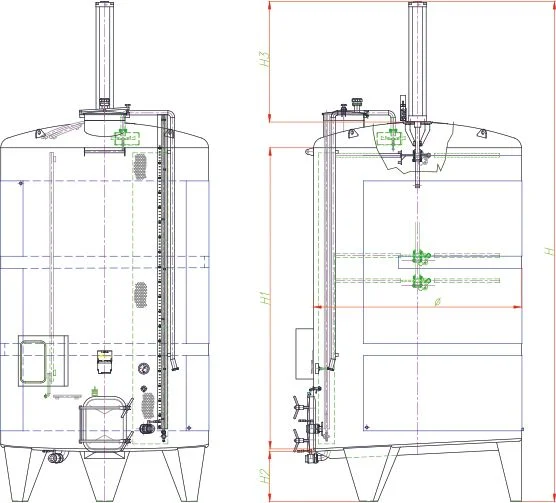

The “Wineficator Romat” is a punch-down fermenter designed to make pigéage easy.

A three-blade impeller suppressor breaks up and submerges the pomace cap, extracting color, tannins, flavor and aromas from the marc. A special mechanism rotates the suppressor blades for 20° on each press.

The HELI rotating sprinkler evenly soaks the pomace cap in the tank, while a built-in sieve separates the solid substance from the liquid.

Rotating paddles at the bottom of the punch-down wine fermentation tank are activated to fully unload the pomace from the vessel.

A programmable, touchscreen control panel serves as a suppressor, temperature and pump regulator, allowing you to automatize the entire process.

The large, dimpled jacket makes sure the temperature inside the punch-down fermenter is always optimal. Thanks to the vertical construction of the cooling jacket, the stored liquids will be efficiently chilled even if the tank is not full to the brim.

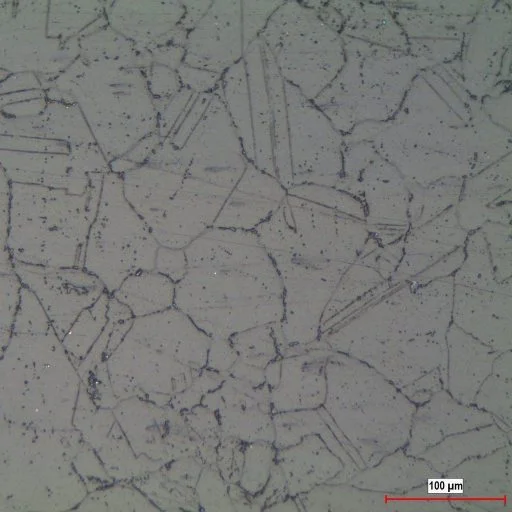

Durable, high-quality materials enable the wine fermentation tank to stay in pristine condition, even after years of professional usage.

![[Bottom] Sloped](https://letina.com/wp-content/uploads/tank-parts-bottoms-b4-sloped.jpg.webp)

![[Bottom] Sloped](https://letina.com/wp-content/uploads/tank-parts-bottoms-b4-sloped.jpg.webp)

![[Top] Rounded Eccentric](https://letina.com/wp-content/uploads/tank-parts-tops-t4-rounded.jpg.webp)

![[Top] Rounded Eccentric](https://letina.com/wp-content/uploads/tank-parts-tops-t4-rounded.jpg.webp)

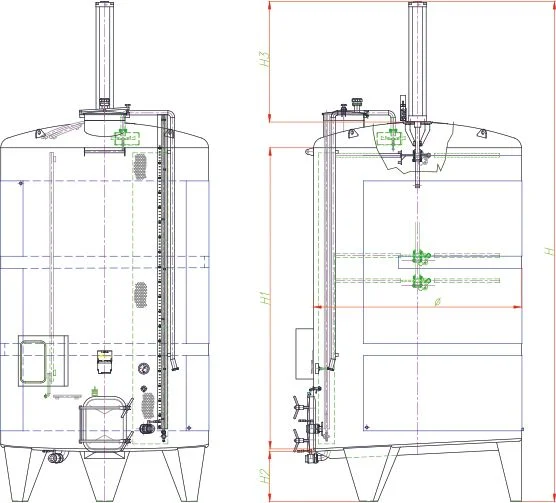

| Type | Capacity (L) | Capacity (US gal) | Diameter (mm) | Total Height (mm) | Shell Height (mm) | Bottom | Top |

|---|---|---|---|---|---|---|---|

| VIP2400A14 | 2400 | 634 | 1402 | 3182 | 1500 | B4 | T4 |

| VIP3200A14 | 3200 | 845 | 1402 | 3682 | 2000 | B4 | T4 |

| VIP4000A14 | 4000 | 1057 | 1402 | 4182 | 2500 | B4 | T4 |

| VIP4200A16 | 4200 | 1110 | 1593 | 3700 | 2000 | B4 | T4 |

| VIP5100A18 | 5100 | 1347 | 1752 | 3740 | 2000 | B4 | T4 |

| VIP5200A16 | 5200 | 1374 | 1593 | 4216 | 2500 | B4 | T4 |

| VIP6200A16 | 6200 | 1638 | 1593 | 4716 | 3000 | B4 | T4 |

| VIP6300A18 | 6300 | 1664 | 1752 | 4240 | 2500 | B4 | T4 |

| VIP7500A18 | 7500 | 1982 | 1752 | 4740 | 3000 | B4 | T4 |

| VIP8900A21 | 8900 | 2351 | 2071 | 4490 | 2500 | B4 | T4 |

| VIP10500A21 | 10500 | 2774 | 2072 | 4990 | 3000 | B4 | T4 |

| VIP12300A22 | 12300 | 3250 | 2230 | 4996 | 3000 | B4 | T4 |

| VIP13900A21 | 13900 | 3672 | 2073 | 5990 | 4000 | B4 | T4 |

| VIP14100A24 | 14100 | 3725 | 2389 | 4998 | 3000 | B4 | T4 |

| VIP14200A22 | 14200 | 3752 | 2230 | 5496 | 3500 | B4 | T4 |

| VIP15500A25 | 15500 | 4095 | 2501 | 4980 | 3000 | B4 | T4 |

| VIP16200A22 | 16200 | 4280 | 2230 | 5996 | 4000 | B4 | T4 |

| VIP16400A24 | 16400 | 4333 | 2389 | 5498 | 3500 | B4 | T4 |

| VIP18000A25 | 18000 | 4756 | 2501 | 5480 | 3500 | B4 | T4 |

| VIP18300A27 | 18300 | 4835 | 2708 | 5095 | 3000 | B4 | T4 |

| VIP18600A24 | 18600 | 4914 | 2389 | 5998 | 4000 | B4 | T4 |

| VIP20400A25 | 20400 | 5390 | 2501 | 5980 | 4000 | B4 | T4 |

| VIP21200A27 | 21200 | 5601 | 2708 | 5595 | 3500 | B4 | T4 |

| VIP24000A27 | 24000 | 6341 | 2708 | 6095 | 4000 | B4 | T4 |

| VIP25300A25 | 25300 | 6684 | 2501 | 6980 | 5000 | B4 | T4 |

| VIP29800A27 | 29800 | 7873 | 2708 | 7095 | 5000 | B4 | T4 |