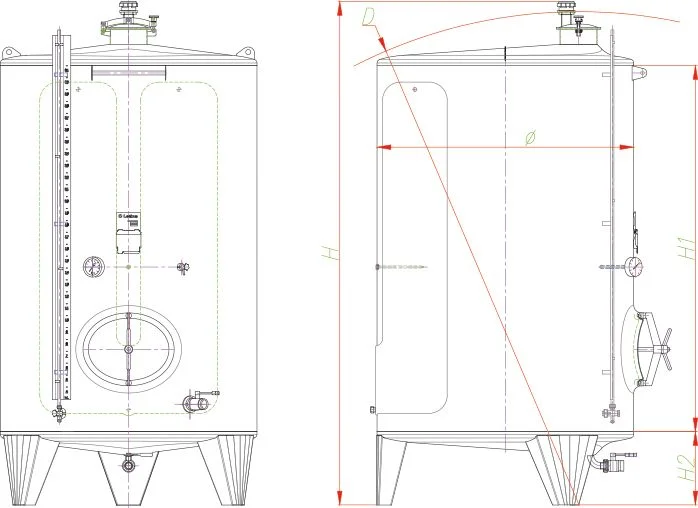

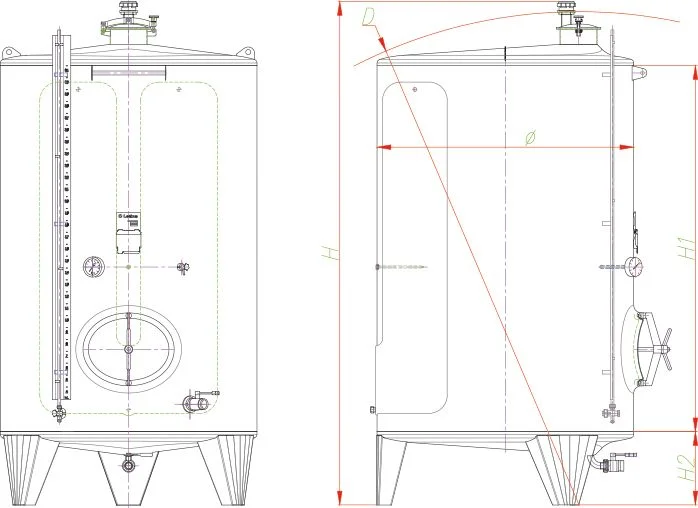

This stainless steel storage tank is one of the oldest models in Letina’s lineup. Tried and tested throughout the years, it has proven its versatility and value time and time again.

Thanks to constant design improvements, the closed tank got better over the years – just like the wine it’s designed to contain.

Whether you want a simple storage tank, a fermentation tank, something to age your product in or even a mixing vessel – this closed top tank can do it all.

A large, dimpled jacket makes sure the temperature inside the sealed tank is always optimal. Thanks to the vertical construction of the cooling jacket, the stored liquids will be efficiently chilled even if the closed tank is not full to the brim.

Durable, high-quality materials enable the storage tank to stay in pristine condition, even after years of professional usage.

![Huge [Z] Closed storage tank by Letina (100 000 L) loaded on a truck.](https://letina.com/wp-content/uploads/z-100000-7-1-512x384.jpg.webp)

![Huge [Z] Closed storage tank by Letina (100 000 L) loaded on a truck.](https://letina.com/wp-content/uploads/z-100000-7-1-512x384.jpg.webp)

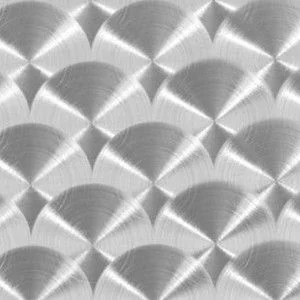

![[Bottom] Conical Eccentric - Press Molded](https://letina.com/wp-content/uploads/tank-parts-bottoms-b1-conical-eccentric.jpg.webp)

![[Bottom] Conical Eccentric - Press Molded](https://letina.com/wp-content/uploads/tank-parts-bottoms-b1-conical-eccentric.jpg.webp)

![[Top] Conical Eccentric - Press Molded](https://letina.com/wp-content/uploads/tank-parts-tops-t1-conical-eccentric.jpg.webp)

![[Top] Conical Eccentric - Press Molded](https://letina.com/wp-content/uploads/tank-parts-tops-t1-conical-eccentric.jpg.webp)

| Type | Capacity (L) | Capacity (US gal) | Diameter (mm) | Total Height (mm) | Shell Height (mm) | Bottom | Top |

|---|---|---|---|---|---|---|---|

| Z500A8 | 500 | 132 | 797 | 1611 | 1000 | B1 | T1 |

| Z600A8 | 600 | 159 | 797 | 1861 | 1250 | B1 | T1 |

| Z750A8 | 750 | 198 | 797 | 2111 | 1500 | B1 | T1 |

| Z750A10 | 750 | 198 | 956 | 1622 | 1000 | B1 | T1 |

| Z900A10 | 900 | 238 | 956 | 1872 | 1250 | B1 | T1 |

| Z1000A8 | 1000 | 264 | 797 | 2611 | 2000 | B1 | T1 |

| Z1040A10 | 1040 | 275 | 956 | 2022 | 1400 | B1 | T1 |

| Z1100A10 | 1100 | 291 | 956 | 2122 | 1500 | B1 | T1 |

| Z1250A8 | 1250 | 330 | 797 | 3111 | 2500 | B1 | T1 |

| Z1250A11 | 1250 | 330 | 1116 | 1884 | 1250 | B1 | T1 |

| Z1450A10 | 1450 | 383 | 956 | 2622 | 2000 | B1 | T1 |

| Z1500A8 | 1500 | 396 | 797 | 3611 | 3000 | B1 | T1 |

| Z1500A11 | 1500 | 396 | 1116 | 2134 | 1500 | B1 | T1 |

| Z1800A10 | 1800 | 476 | 956 | 3122 | 2500 | B1 | T1 |

| Z2000A11 | 2000 | 528 | 1116 | 2634 | 2000 | B1 | T1 |

| Z2000A13 | 2000 | 528 | 1275 | 2245 | 1500 | B1 | T1 |

| Z2150A10 | 2150 | 568 | 956 | 3622 | 3000 | B1 | T1 |

| Z2400A14 | 2400 | 634 | 1402 | 2250 | 1500 | B1 | T1 |

| Z2450A11 | 2450 | 647 | 1116 | 3134 | 2500 | B1 | T1 |

| Z2600A13 | 2600 | 687 | 1275 | 2745 | 2000 | B1 | T1 |

| Z2950A11 | 2950 | 779 | 1116 | 3634 | 3000 | B1 | T1 |

| Z3200A14 | 3200 | 845 | 1402 | 2750 | 2000 | B1 | T1 |

| Z3250A13 | 3250 | 859 | 1275 | 3245 | 2500 | B1 | T1 |

| Z3900A13 | 3900 | 1030 | 1275 | 3745 | 3000 | B1 | T1 |

| Z3950A11 | 3950 | 1044 | 1116 | 4634 | 4000 | B1 | T1 |

| Z3950A14 | 3950 | 1044 | 1402 | 3250 | 2500 | B1 | T1 |

| Z4150A16 | 4150 | 1096 | 1593 | 2764 | 2000 | B1 | T1 |

| Z4700A14 | 4700 | 1242 | 1402 | 3750 | 3000 | B1 | T1 |

| Z5000A18 | 5000 | 1321 | 1752 | 2775 | 2000 | B1 | T1 |

| Z5100A16 | 5100 | 1347 | 1593 | 3264 | 2500 | B1 | T1 |

| Z5150A13 | 5150 | 1361 | 1275 | 4745 | 4000 | B1 | T1 |

| Z6000A19 | 6000 | 1585 | 1911 | 2938 | 2000 | B2 | T2 |

| Z6100A16 | 6100 | 1612 | 1593 | 3764 | 3000 | B1 | T1 |

| Z6200A18 | 6200 | 1638 | 1752 | 3275 | 2500 | B1 | T1 |

| Z6250A14 | 6250 | 1651 | 1402 | 4750 | 4000 | B1 | T1 |

| Z7450A18 | 7450 | 1968 | 1752 | 3775 | 3000 | B1 | T1 |

| Z7450A19 | 7450 | 1968 | 1911 | 3438 | 2500 | B2 | T2 |

| Z8100A16 | 8100 | 2140 | 1593 | 4764 | 4000 | B1 | T1 |

| Z8750A21 | 8750 | 2312 | 2071 | 3455 | 2500 | B3 | T2 |

| Z8850A19 | 8850 | 2338 | 1911 | 3938 | 3000 | B2 | T2 |

| Z9850A18 | 9850 | 2602 | 1752 | 4775 | 4000 | B1 | T1 |

| Z10100A16 | 10100 | 2668 | 1593 | 5764 | 5000 | B1 | T1 |

| Z10200A22 | 10200 | 2695 | 2230 | 3473 | 2500 | B3 | T2 |

| Z10400A21 | 10400 | 2748 | 2071 | 3955 | 3000 | B3 | T2 |

| Z11700A19 | 11700 | 3091 | 1911 | 4938 | 4000 | B2 | T2 |

| Z12200A18 | 12200 | 3223 | 1752 | 5775 | 5000 | B1 | T1 |

| Z12200A22 | 12200 | 3223 | 2230 | 3973 | 3000 | B3 | T2 |

| Z13800A21 | 13800 | 3646 | 2071 | 4955 | 4000 | B3 | T2 |

| Z14600A19 | 14600 | 3857 | 1911 | 5938 | 5000 | B2 | T2 |

| Z15300A25 | 15300 | 4042 | 2501 | 4002 | 3000 | B3 | T2 |

| Z16100A22 | 16100 | 4254 | 2230 | 4973 | 4000 | B3 | T2 |

| Z17100A21 | 17100 | 4518 | 2071 | 5955 | 5000 | B3 | T2 |

| Z20000A22 | 20000 | 5284 | 2230 | 5973 | 5000 | B3 | T2 |

| Z20200A25 | 20200 | 5337 | 2501 | 5002 | 4000 | B3 | T2 |

| Z20500A21 | 20500 | 5416 | 2071 | 6955 | 6000 | B3 | T2 |

| Z23900A22 | 23900 | 6314 | 2230 | 6973 | 6000 | B3 | T2 |

| Z25100A25 | 25100 | 6631 | 2501 | 6002 | 5000 | B3 | T2 |

| Z30000A25 | 30000 | 7926 | 2501 | 7002 | 6000 | B3 | T2 |

| Z34900A25 | 34900 | 9221 | 2501 | 8002 | 7000 | B3 | T2 |

| Z39800A25 | 39800 | 10515 | 2501 | 9002 | 8000 | B3 | T2 |

A closed tank, also referred to as a sealed tank or closed top tank, is any fixed capacity storage vessel. The top of this type of tanks is sealed by welding it to the body, hence the name sealed tank.

The opposite to a closed tank is a variable capacity tank.

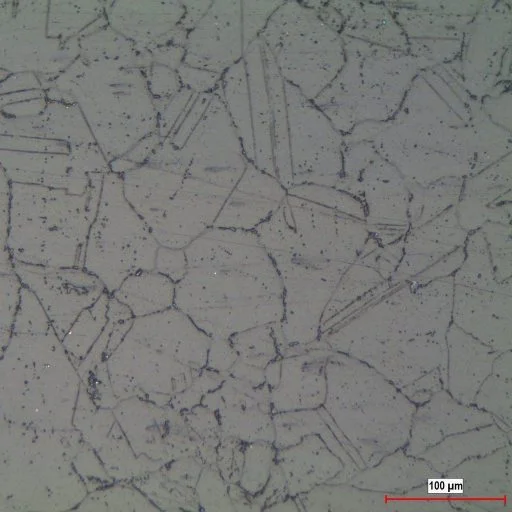

The closed tank is a completely sanitary vessel made out of AISI 304 stainless steel. It is suitable as a storage tank for a wide variety of liquids and foodstuffs. Wine, beer, liquor, dairy, confectionery, cosmetics, pharmaceuticals – even corrosive chemicals can be stored in the closed tank with an upgrade to AISI 316L stainless steel.

Learn more about the different properties of AISI 304 and AISI 316 stainless steels.

The closed tank was initially designed for the wine industry and intended as a storage and fermentation vessel. Since then, it received many design upgrades. Now, the closed tank is suitable for storage, fermentation and mixing of any sanitary liquid or powder.