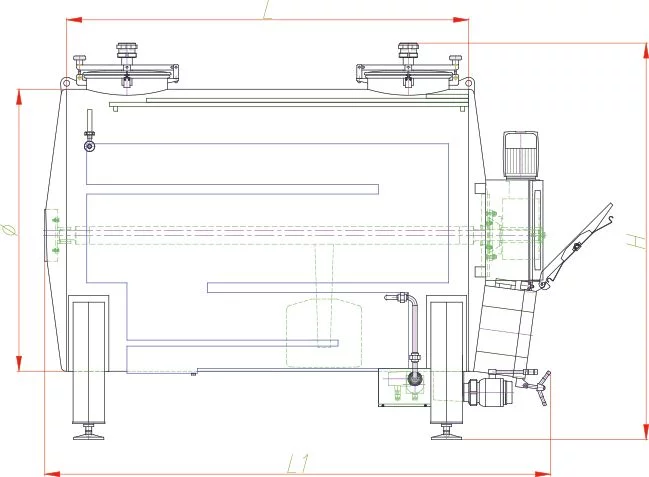

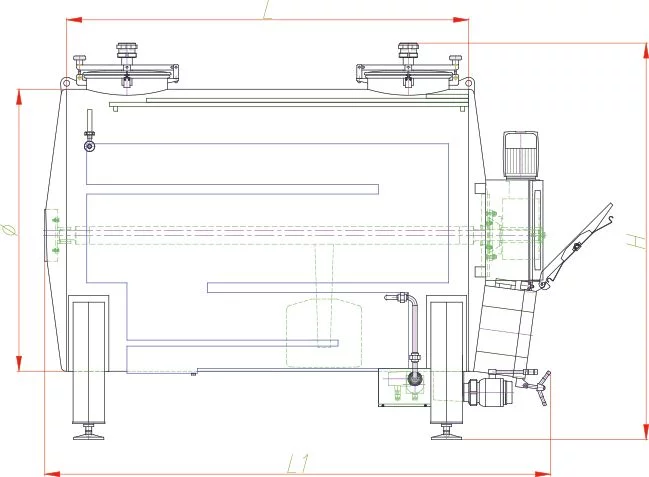

The “Wineficator Winematic” is a horizontal fermenter designed to perfect the maceration of red wine.

A geared motor powers an anchor type agitator spanning the length of the fermentation tank. The motor is equipped with an inverter, allowing an adjustable speed of 0 to 5 rpm – in either direction. The gentle mixing breaks up and submerges the pomace cap, extracting color, tannins, flavor and aromas from the marc.

The very same agitator is part of a specially designed system that enables an automatic discharge of pomace from the horizontal fermenter.

A programmable, touchscreen control panel serves as a rotation, discharge and temperature regulator, allowing you to automatize the entire process.

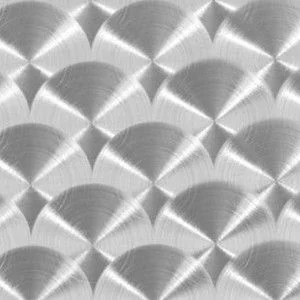

The large, dimpled jacket makes sure the temperature inside the horizontal fermentation tank is always optimal. Thanks to the vertical construction of the cooling jacket, the stored liquids will be efficiently chilled even if the tank is not full to the brim.

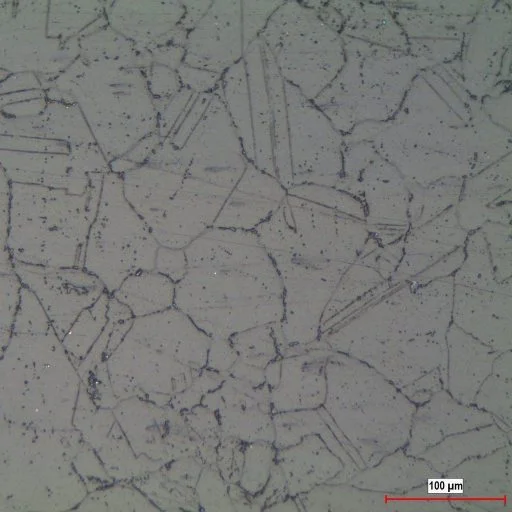

Durable, high-quality materials enable the wine fermenter to stay in pristine condition, even after years of professional usage.

| Type | Capacity (L) | Capacity (US gal) | Diameter (mm) | Total Length (mm) | Shell Length (mm) | Total Height (mm) | # of Paddles |

|---|---|---|---|---|---|---|---|

| VIN3200A14 | 3200 | 845 | 1403 | 2621 | 2000 | 2000 | 7 |

| VIN4000A14 | 4000 | 1057 | 1403 | 3121 | 2500 | 2000 | 8 |

| VIN4100A16 | 4100 | 1083 | 1594 | 2635 | 2000 | 2300 | 7 |

| VIN5000A18 | 5000 | 1321 | 1753 | 2646 | 2000 | 2450 | 7 |

| VIN5100A16 | 5100 | 1347 | 1594 | 3135 | 2500 | 2300 | 8 |

| VIN6200A18 | 6200 | 1638 | 1753 | 3146 | 2500 | 2450 | 8 |

| VIN7400A18 | 7400 | 1955 | 1753 | 3646 | 3000 | 2450 | 10 |

| VIN7500A19 | 7500 | 1982 | 1912 | 3157 | 2500 | 2700 | 8 |

| VIN8900A19 | 8900 | 2351 | 1912 | 3657 | 3000 | 2700 | 10 |

| VIN10500A21 | 10500 | 2774 | 2072 | 3680 | 3000 | 2800 | 10 |

| VIN12200A22 | 12200 | 3223 | 2231 | 3680 | 3000 | 3000 | 10 |

| VIN13800A21 | 13800 | 3646 | 2072 | 4680 | 4000 | 2800 | 14 |

| VIN15400A25 | 15400 | 4069 | 2502 | 3699 | 3000 | 3300 | 10 |

| VIN16100A22 | 16100 | 4254 | 2231 | 4680 | 4000 | 3000 | 14 |

| VIN20300A25 | 20300 | 5363 | 2502 | 4699 | 4000 | 3300 | 14 |

| VIN25000A25 | 25000 | 6605 | 2502 | 5850 | 5000 | 3300 | 10 |

| VIN30000A25 | 30000 | 7926 | 2502 | 6850 | 6000 | 3300 | 14 |