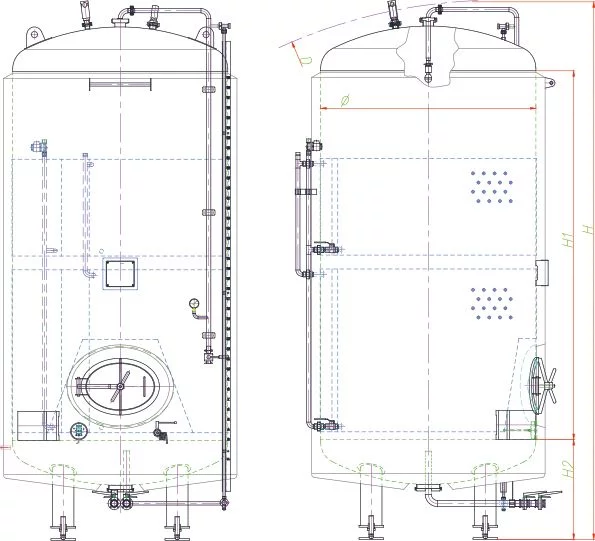

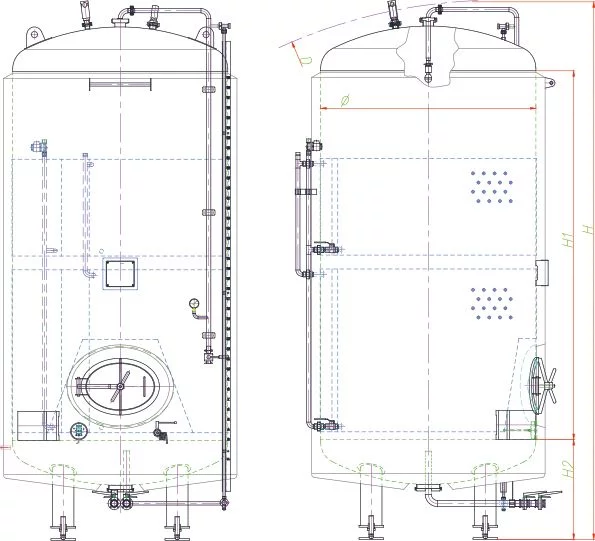

A brite tank is a vessel used to mature, clarify and carbonate beer. It gets its name after the clear, bright beer stored and processed in it. Most breweries use brite tanks as serving vessels, too.

While it would take around two weeks for beer to clarify and carbonate in a conical fermenter, a bright beer tank needs less than two days. Typical breweries have one brite tank for every four to five conicals.

A special dished bottom collects the leftover yeast, letting you draw clear beer down to the very last drop. Unlike conical fermenters and other vessels, bright beer tanks yield close to 100% of the volume, letting you easily perform packaging calculations.

A large, dimpled jacket on the coat makes sure the temperature inside the brite tank is always optimal. Thanks to the vertical construction of the cooling jacket, the stored liquids will be efficiently chilled even if the tank is not full to the brim.

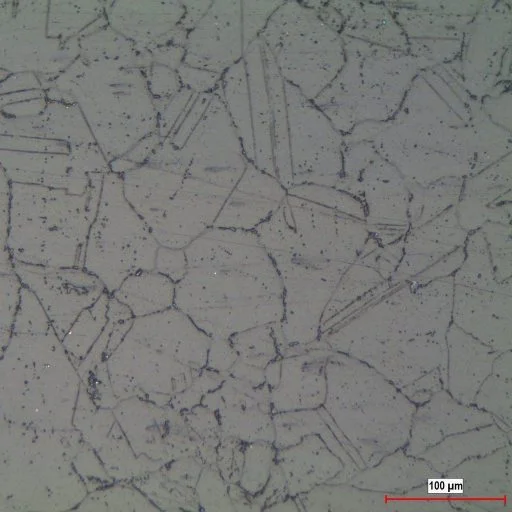

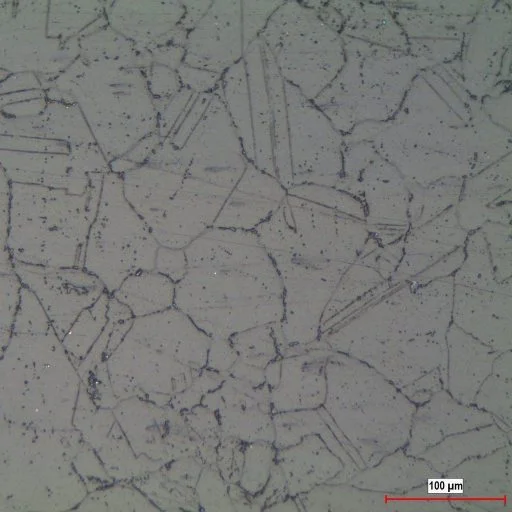

Durable, high-quality materials enable the bright beer tank to stay in pristine condition, even after years of professional usage.

The bright beer tank is made out of AISI 304 quality stainless steel. An upgrade to AISI 316L stainless steel is available for high-corrosion environments.

A high-polish, mirrored finish is applied to the outside of the brite tank. Marbled, Matte and Scotch Brite finishes are also available upon request. The inside is BA (IIId) Mirror polished.

![[Bottom] Rounded Torispherical - DIN28011](https://letina.com/wp-content/uploads/tank-parts-bottoms-b8-DIN28011.jpg.webp)

![[Bottom] Rounded Torispherical - DIN28011](https://letina.com/wp-content/uploads/tank-parts-bottoms-b8-DIN28011.jpg.webp)

![[Top] Rounded Torispherical - DIN28011](https://letina.com/wp-content/uploads/tank-parts-tops-t5-DIN28011.jpg.webp)

![[Top] Rounded Torispherical - DIN28011](https://letina.com/wp-content/uploads/tank-parts-tops-t5-DIN28011.jpg.webp)

The tank is designed, manufactured, inspected and tested to safely perform at high pressure levels. Our CE PED certificate ensures maximum quality and safe use.

| Type | Capacity (L) | Capacity (US gal) | Total Volume (L) | Total Volume (US gal) | Diameter (mm) | Total Height (mm) | Shell Height (mm) |

|---|---|---|---|---|---|---|---|

| ZBB500A9 | 500 | 132 | 614 | 135 | 800 | 1740 | 1000 |

| ZBB1000A11 | 1000 | 264 | 1265 | 278 | 957 | 2370 | 1500 |

| ZBB1500A12 | 1500 | 396 | 1760 | 387 | 1116 | 2450 | 1500 |

| ZBB2000A14 | 2000 | 528 | 2350 | 517 | 1275 | 2733 | 1500 |

| ZBB3000A15 | 3000 | 793 | 3650 | 803 | 1400 | 3064 | 2000 |

| ZBB4000A17 | 4000 | 1057 | 4865 | 1070 | 1600 | 3200 | 2000 |

| ZBB5000A19 | 5000 | 1321 | 5913 | 1301 | 1750 | 3230 | 2000 |

| ZBB6000A19 | 6000 | 1585 | 7100 | 1562 | 1750 | 3730 | 2500 |

| ZBB8000A20 | 8000 | 2114 | 9300 | 2046 | 1911 | 4125 | 2750 |

| ZBB10000A22 | 10000 | 2642 | 11900 | 2618 | 2071 | 4500 | 3000 |

| ZBB12000A23 | 12000 | 3170 | 13550 | 2981 | 2200 | 4620 | 3000 |

| ZBB16000A23 | 16000 | 4227 | 19200 | 4223 | 2200 | 6120 | 4500 |

A brite tank, also known as a bright beer tank, is a vessel used for the maturation, clarification and carbonation of beer. It gets its name after the clear, bright beer that results from is usage.

It’s usually equipped with some sort of carbonation system designed to significantly cut down carbonation times.

Most brewers use the bright beer tank as a serving vessel and for general storage.

The required number of bright beer tanks varies depending on the duration of the fermentation process and the volume of the tanks involved.

Typically, breweries have one brite tank for every four or five fermentation vessels.

The duration of the carbonation process depends on many factors, some of them are the desired carb limit and CO2 pressure used.

A bright beer tank takes around a day or two to clarify and carbonate beer, depending on the desired CO2 volume. Commercial breweries speed it up by force carbonation.

Typical fermentation vessels would take around two weeks to achieve the same effect as a brite tank does in a couple of days.

Commercial breweries use a process known as burst carbing. It is essentially setting the carbonation system to very high pressures until the desired carb limit is reached, which is then lowered to reasonable pressures for serving purposes.

The PSI used to carbonate beer depends on the desired beer CO2 volume and how quickly you want it carbonated.

Brite tanks are built to withstand high pressures and many breweries use this to their advantage by setting the input pressure up to 40 PSI. when the desired beer CO2 volume is achieved, they turn down the pressure to something like 10-13 PSI for serving purposes.