This floating lid tank is a variable capacity tank designed for hobbyists and amateurs. The coat thickness is almost half of PZP/PZPK’s, making it much more affordable – but less suitable for professional use.

It has a floating cap, allowing you to minimize oxygenation, no matter how much liquid is stored in the tank.

Unlike the PZP, this tank has no lifting arm option nor an inflatable gasket. The air-tight seal is achieved by applying oil around the floating lid.

Durable, high-quality materials enable the variable capacity tank to stay in pristine condition, even after years of professional usage.

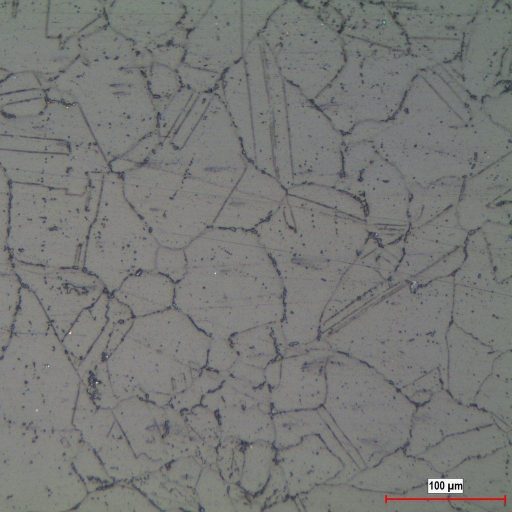

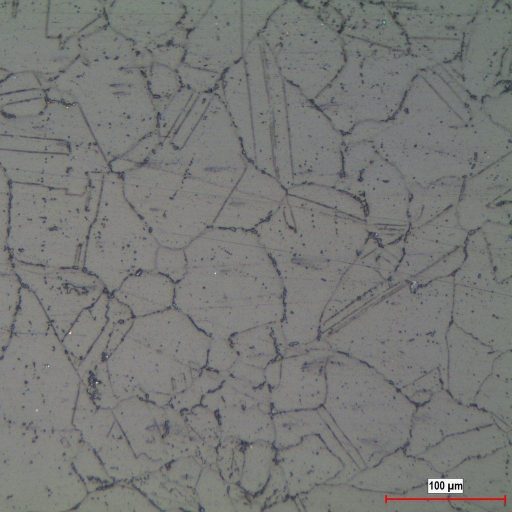

The floating lid VCT is made out of AISI 304 quality stainless steel. An upgrade to AISI 316L stainless steel is available for high-corrosion environments.

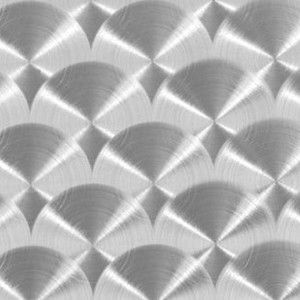

A high-polish, marbled finish is applied to the outside of the floating lid tank. Matte and Scotch Brite finishes are also available upon request. The inside is BA (IIId) polished.

The floating lid cap sits just above the stored liquid surface - making the floating lid tank the perfect fit for small and growing wineries. An air-tight seal is achieved by applying oil around the lid.

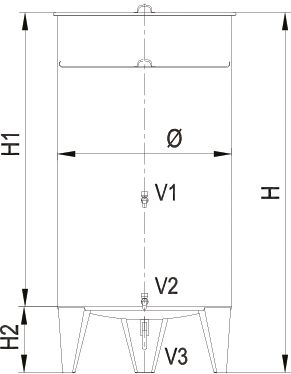

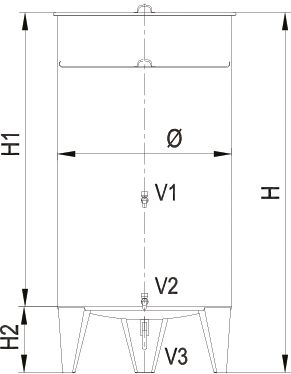

| Type | Capacity (L) | Capacity (US gal) | Diameter (mm) | Total Height (mm) | Shell Height (mm) | V1 | V2 | V3 |

|---|---|---|---|---|---|---|---|---|

| PP15A2 | 15 | 4 | 246 | 530 | 320 | - | 1/2" | - |

| PP50A4 | 50 | 13 | 360 | 800 | 500 | - | 1/2" | - |

| PP100A4 | 100 | 26 | 420 | 1050 | 750 | 1/2" | 1/2" | - |

| PP150A5 | 150 | 40 | 510 | 1050 | 750 | 1/2" | 1/2" | - |

| PP200A5 | 200 | 53 | 510 | 1300 | 1000 | 1/2" | 1/2" | - |

| PP320A6 | 320 | 85 | 637 | 1300 | 1000 | 1/2" | 1/2" | 3/4" |

| PP400A6 | 400 | 106 | 637 | 1550 | 1250 | 1/2" | 1/2" | 3/4" |

| PP520A7 | 520 | 137 | 730 | 1550 | 1250 | 1/2" | 1/2" | 3/4" |

| PP620A8 | 620 | 164 | 797 | 1550 | 1250 | 1/2" | 1/2" | 3/4" |

| PP900A10 | 900 | 238 | 956 | 1550 | 1250 | 1/2" | 1" | 1" |

| PP1100A10 | 1100 | 291 | 956 | 1800 | 1500 | 1/2" | 1" | 1" |

| PP1500A11 | 1500 | 396 | 1116 | 1800 | 1500 | 1/2" | 5/4" | 5/4" |

| PP2000A11 | 2000 | 528 | 1116 | 2300 | 2000 | 1/2" | 5/4" | 5/4" |