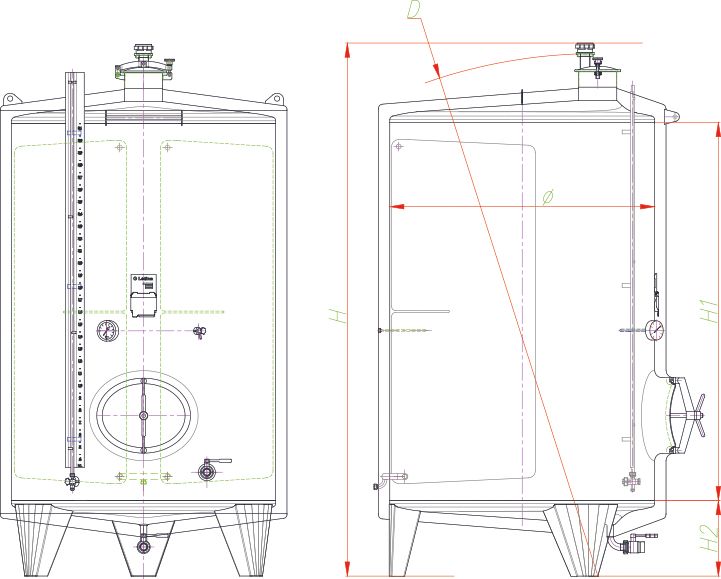

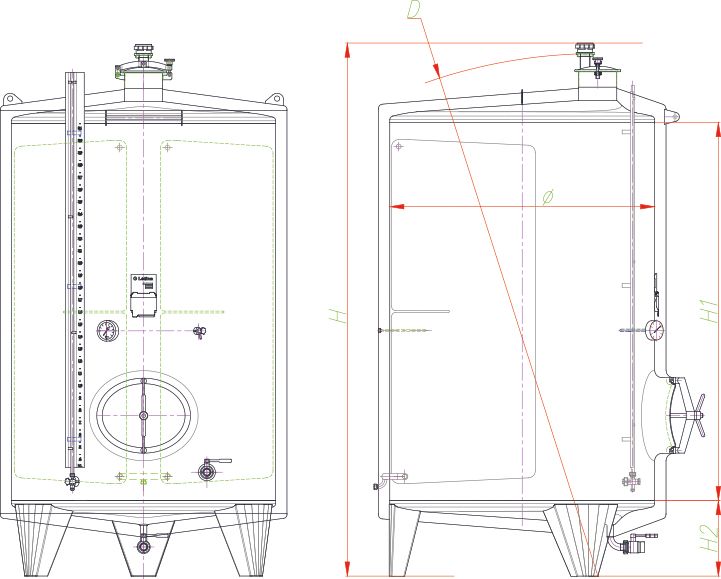

The insulated tank was designed for processing that requires precise temperature regulation.

This tank is much like other sealed vessels, with one major difference – the stainless steel tank is wrapped with a thick layer of polyurethane foam.

Polyurethane foam is one of the best choices of insulation material, especially when dealing with fluids. It offers great thermal insulation, is resistant to moisture and water and has a low density, making it lighter.

A large, dimpled jacket makes sure the temperature inside the insulated tank is always optimal. Thanks to the vertical construction of the cooling jacket, the stored liquids will be efficiently chilled even if the tank is not full to the brim.

Combined with the PU foam layer, the insulated tank jacket makes your temperature control system even more efficient and cost-effective.

Durable, high-quality materials enable the tank to stay in pristine condition, even after years of professional usage.

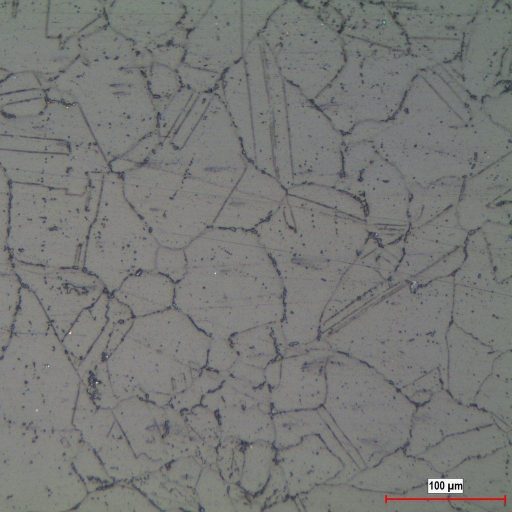

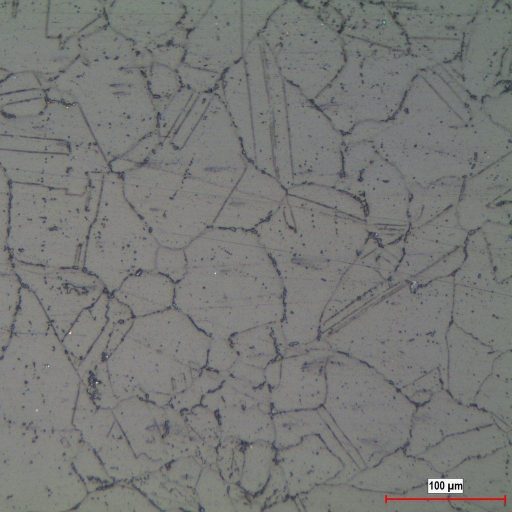

The insulated tank is made out of AISI 304 quality stainless steel. An upgrade to AISI 316L stainless steel is available for high-corrosion environments.

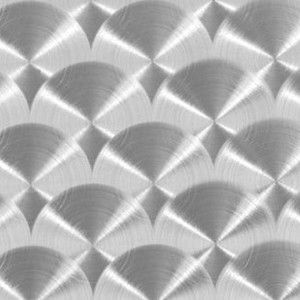

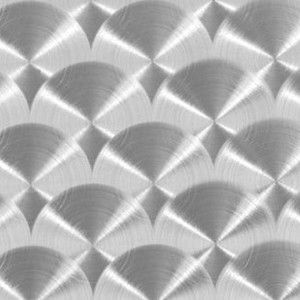

A high-polish, marbled finish is applied to the outside of the insulated tank. Matte and Scotch Brite finishes are also available upon request. The inside is BA (IIId) polished.

The insulated tank comes with a conical eccentric press-molded bottom by default. Large tanks come with a centered bottom to keep discharge easy.

![[Bottom] Conical Eccentric - Press Molded](https://letina.com/wp-content/uploads/tank-parts-bottoms-b1-conical-eccentric.jpg)

![[Bottom] Conical Eccentric - Press Molded](https://letina.com/wp-content/uploads/tank-parts-bottoms-b1-conical-eccentric.jpg)

A press-molded eccentric conical top comes standard with all insulated storage tanks. Other head shapes are available upon request.

![[Top] Conical Eccentric - Press Molded](https://letina.com/wp-content/uploads/tank-parts-tops-t1-conical-eccentric.jpg)

![[Top] Conical Eccentric - Press Molded](https://letina.com/wp-content/uploads/tank-parts-tops-t1-conical-eccentric.jpg)

The tank is wrapped with a thick layer of polyurethane foam which provides great thermal insulation. The PU foam is resistant to moisture and water, making it perfect for stainless steel tanks.

| Type | Capacity (L) | Capacity (US gal) | Diameter (mm) | Total Height (mm) | Shell Height (mm) | Bottom | Top |

|---|---|---|---|---|---|---|---|

| IZO500A9 | 500 | 132 | 797 | 1691 | 1000 | B1 | T1 |

| IZO600A9 | 600 | 159 | 797 | 1941 | 1250 | B1 | T1 |

| IZO750A9 | 750 | 198 | 797 | 2191 | 1500 | B1 | T1 |

| IZO750A11 | 750 | 198 | 956 | 1702 | 1000 | B1 | T1 |

| IZO900A11 | 900 | 238 | 956 | 1952 | 1250 | B1 | T1 |

| IZO1000A9 | 1000 | 264 | 797 | 2691 | 2000 | B1 | T1 |

| IZO1040A11 | 1040 | 275 | 956 | 2102 | 1400 | B1 | T1 |

| IZO1100A11 | 1100 | 291 | 956 | 2202 | 1500 | B1 | T1 |

| IZO1250A9 | 1250 | 330 | 797 | 3191 | 2500 | B1 | T1 |

| IZO1250A12 | 1250 | 330 | 1116 | 1960 | 1250 | B1 | T1 |

| IZO1450A11 | 1450 | 383 | 956 | 2702 | 2000 | B1 | T1 |

| IZO1500A9 | 1500 | 396 | 797 | 3691 | 3000 | B1 | T1 |

| IZO1500A12 | 1500 | 396 | 1116 | 2210 | 1500 | B1 | T1 |

| IZO1800A11 | 1800 | 476 | 956 | 3202 | 2500 | B1 | T1 |

| IZO2000A12 | 2000 | 528 | 1116 | 2710 | 2000 | B1 | T1 |

| IZO2000A14 | 2000 | 528 | 1275 | 2325 | 1500 | B1 | T1 |

| IZO2150A11 | 2150 | 568 | 956 | 3702 | 3000 | B1 | T1 |

| IZO2400A15 | 2400 | 634 | 1402 | 2330 | 1500 | B1 | T1 |

| IZO2450A12 | 2450 | 647 | 1116 | 3210 | 2500 | B1 | T1 |

| IZO2600A14 | 2600 | 687 | 1275 | 2825 | 2000 | B1 | T1 |

| IZO2950A12 | 2950 | 779 | 1116 | 3710 | 3000 | B1 | T1 |

| IZO3200A15 | 3200 | 845 | 1402 | 2830 | 2000 | B1 | T1 |

| IZO3250A14 | 3250 | 859 | 1275 | 3325 | 2500 | B1 | T1 |

| IZO3900A14 | 3900 | 1030 | 1275 | 3825 | 3000 | B1 | T1 |

| IZO3950A12 | 3950 | 1044 | 1116 | 4710 | 4000 | B1 | T1 |

| IZO3950A15 | 3950 | 1044 | 1402 | 3330 | 2500 | B1 | T1 |

| IZO4150A17 | 4150 | 1096 | 1593 | 2844 | 2000 | B1 | T1 |

| IZO4700A15 | 4700 | 1242 | 1402 | 3830 | 3000 | B1 | T1 |

| IZO5000A19 | 5000 | 1321 | 1752 | 2855 | 2000 | B1 | T1 |

| IZO5100A17 | 5100 | 1347 | 1593 | 3344 | 2500 | B1 | T1 |

| IZO5150A14 | 5150 | 1361 | 1275 | 4825 | 4000 | B1 | T1 |

| IZO6000A20 | 6000 | 1585 | 1911 | 3018 | 2000 | B2 | T2 |

| IZO6100A17 | 6100 | 1612 | 1593 | 3844 | 3000 | B1 | T1 |

| IZO6200A19 | 6200 | 1638 | 1752 | 3355 | 2500 | B1 | T1 |

| IZO6250A15 | 6250 | 1651 | 1402 | 4830 | 4000 | B1 | T1 |

| IZO7450A19 | 7450 | 1968 | 1752 | 3855 | 3000 | B1 | T1 |

| IZO7450A20 | 7450 | 1968 | 1911 | 3518 | 2500 | B2 | T2 |

| IZO8100A17 | 8100 | 2140 | 1593 | 4844 | 4000 | B1 | T1 |

| IZO8750A22 | 8750 | 2312 | 2071 | 3535 | 2500 | B3 | T2 |

| IZO8850A20 | 8850 | 2338 | 1911 | 4018 | 3000 | B2 | T2 |

| IZO9850A19 | 9850 | 2602 | 1752 | 4855 | 4000 | B1 | T1 |

| IZO10100A17 | 10100 | 2668 | 1593 | 5844 | 5000 | B1 | T1 |

| IZO10200A23 | 10200 | 2695 | 2230 | 3553 | 2500 | B3 | T2 |

| IZO10400A22 | 10400 | 2748 | 2071 | 4035 | 3000 | B3 | T2 |

| IZO11700A20 | 11700 | 3091 | 1911 | 5018 | 4000 | B2 | T2 |

| IZO12200A19 | 12200 | 3223 | 1752 | 5855 | 5000 | B1 | T1 |

| IZO12200A23 | 12200 | 3223 | 2230 | 4053 | 3000 | B3 | T2 |

| IZO13800A22 | 13800 | 3646 | 2071 | 5035 | 4000 | B3 | T2 |

| IZO14600A20 | 14600 | 3857 | 1911 | 6018 | 5000 | B2 | T2 |

| IZO15300A26 | 15300 | 4042 | 2501 | 4082 | 3000 | B3 | T2 |

| IZO16100A23 | 16100 | 4254 | 2230 | 5053 | 4000 | B3 | T2 |

| IZO17100A22 | 17100 | 4518 | 2071 | 6035 | 5000 | B3 | T2 |

| IZO20000A23 | 20000 | 5284 | 2230 | 6053 | 5000 | B3 | T2 |

| IZO20200A26 | 20200 | 5337 | 2501 | 5082 | 4000 | B3 | T2 |

| IZO20500A22 | 20500 | 5416 | 2071 | 7035 | 6000 | B3 | T2 |

| IZO23900A23 | 23900 | 6314 | 2230 | 7053 | 6000 | B3 | T2 |

| IZO25100A26 | 25100 | 6631 | 2501 | 6082 | 5000 | B3 | T2 |

| IZO30000A26 | 30000 | 7926 | 2501 | 7082 | 6000 | B3 | T2 |

| IZO34900A26 | 34900 | 9221 | 2501 | 8082 | 7000 | B3 | T2 |

| IZO39800A26 | 39800 | 10515 | 2501 | 9082 | 8000 | B3 | T2 |