Variable-capacity tanks have recently become a staple of the wine industry. They offer complete control over the fermentation process to small and growing wineries. Even though their yields depend on the annual harvest, they can use the same tank every year.

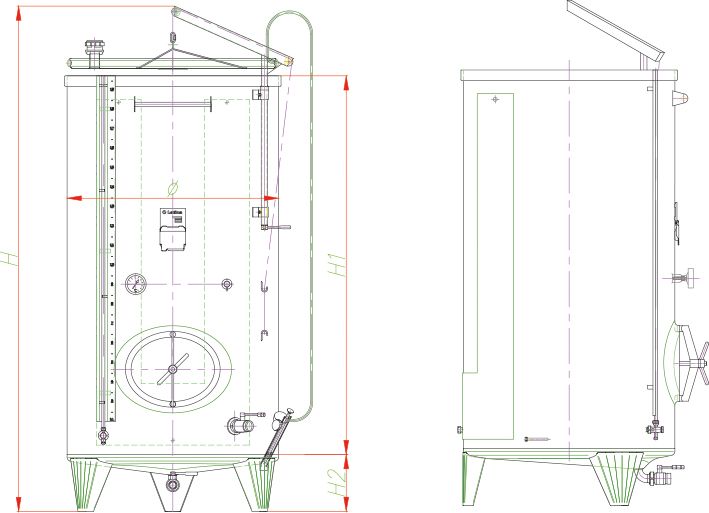

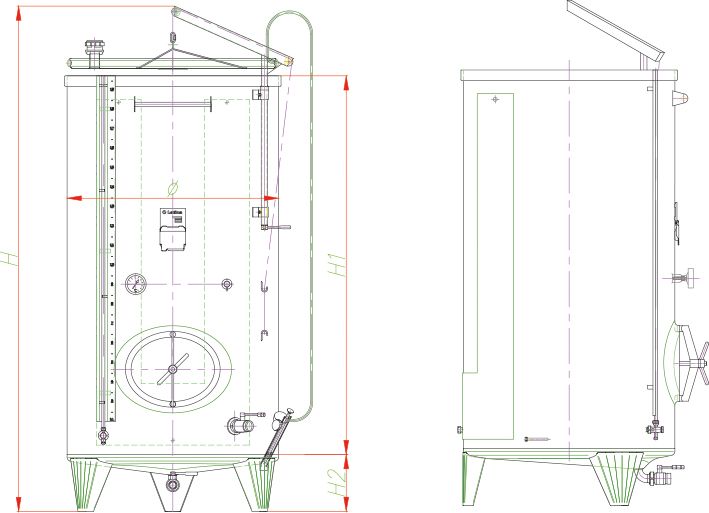

Thanks to the “floating” lid, you don’t have to fill the variable capacity tank to its brim. The inflatable gasket achieves an air-tight seal, preventing accidental oxygen contamination.

Moving the floating lid into place and securing the air seal is easy with the mounted lifting arm and stainless steel hand pump.

Durable, high-quality materials enable the variable capacity tank to stay in pristine condition, even after years of professional usage.

Thanks to the vertical construction of the cooling jacket, the stored liquids will be efficiently chilled even if the tank is not full to the brim.

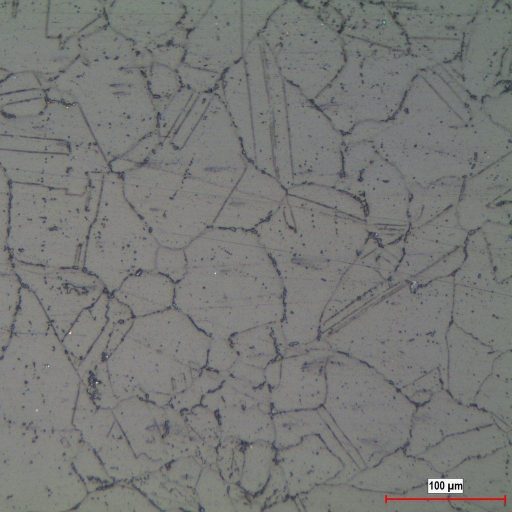

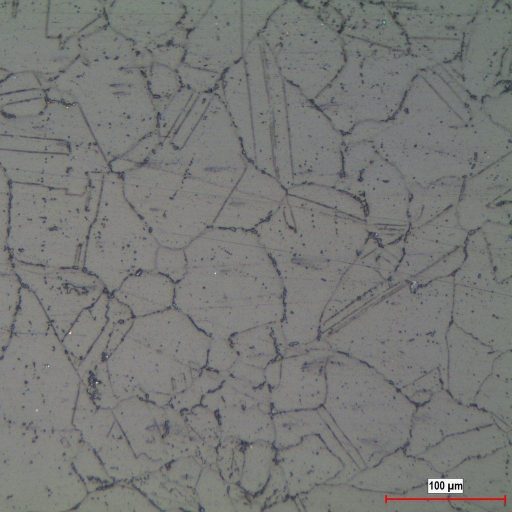

The variable capacity tank is made out of AISI 304 quality stainless steel. An upgrade to AISI 316L stainless steel is available for high-corrosion environments.

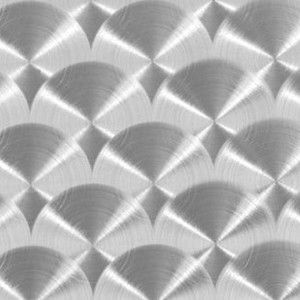

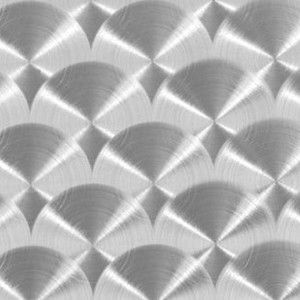

A high-polish, marbled finish is applied to the outside of the variable capacity. Matte and Scotch Brite finishes are also available upon request. The inside is BA (IIId) polished.

This variable volume tank comes with a conical eccentric press-molded bottom by default. Large tanks come with a centered bottom to keep discharge easy.

![[Bottom] Conical Eccentric - Press Molded](https://letina.com/wp-content/uploads/tank-parts-bottoms-b1-conical-eccentric.jpg)

![[Bottom] Conical Eccentric - Press Molded](https://letina.com/wp-content/uploads/tank-parts-bottoms-b1-conical-eccentric.jpg)

| Type | Capacity (L) | Capacity (US gal) | Diameter (mm) | Total Height (mm) | Shell Height (mm) | Bottom |

|---|---|---|---|---|---|---|

| PZP320A6 | 320 | 85 | 638 | 1300 | 1000 | B1 |

| PZP400A6 | 400 | 106 | 638 | 1550 | 1250 | B1 |

| PZP420A7 | 420 | 111 | 731 | 1300 | 1000 | B1 |

| PZP480A6 | 480 | 127 | 638 | 1800 | 1500 | B1 |

| PZP500A8 | 500 | 132 | 797 | 1300 | 1000 | B1 |

| PZP530A7 | 530 | 140 | 731 | 1550 | 1250 | B1 |

| PZP630A7 | 630 | 166 | 731 | 1800 | 1500 | B1 |

| PZP630A8 | 630 | 166 | 797 | 1550 | 1250 | B1 |

| PZP750A8 | 750 | 198 | 797 | 1800 | 1500 | B1 |

| PZP900A10 | 900 | 238 | 956 | 1550 | 1250 | B1 |

| PZP1100A10 | 1100 | 291 | 956 | 2150 | 1500 | B1 |

| PZP1200A11 | 1200 | 317 | 1116 | 1550 | 1250 | B1 |

| PZP1400A10 | 1400 | 370 | 956 | 2650 | 2000 | B1 |

| PZP1500A11 | 1500 | 396 | 1116 | 2220 | 1500 | B1 |

| PZP1900A13 | 1900 | 502 | 1275 | 2350 | 1500 | B1 |

| PZP2000A11 | 2000 | 528 | 1116 | 2700 | 2000 | B1 |

| PZP2300A14 | 2300 | 608 | 1402 | 2350 | 1500 | B1 |

| PZP2500A13 | 2500 | 661 | 1275 | 2850 | 2000 | B1 |

| PZP3100A14 | 3100 | 819 | 1402 | 2850 | 2000 | B1 |

| PZP3200A13 | 3200 | 845 | 1275 | 3350 | 2500 | B1 |

| PZP3900A14 | 3900 | 1030 | 1402 | 3350 | 2500 | B1 |

| PZP4000A16 | 4000 | 1057 | 1593 | 2900 | 2000 | B1 |

| PZP4900A18 | 4900 | 1295 | 1752 | 2950 | 2000 | B1 |

| PZP5000A16 | 5000 | 1321 | 1593 | 3400 | 2500 | B1 |

| PZP6000A16 | 6000 | 1585 | 1593 | 3900 | 3000 | B1 |

| PZP6100A18 | 6100 | 1612 | 1752 | 3450 | 2500 | B1 |

| PZP7300A18 | 7300 | 1929 | 1752 | 3950 | 3000 | B1 |

| PZP7300A19 | 7300 | 1929 | 1911 | 3600 | 2500 | B2 |

| PZP8600A21 | 8600 | 2272 | 2071 | 3600 | 2500 | B3 |

| PZP8700A19 | 8700 | 2299 | 1911 | 4100 | 3000 | B2 |

| PZP10200A21 | 10200 | 2695 | 2071 | 4100 | 3000 | B3 |

| PZP11600A19 | 11600 | 3065 | 1911 | 5100 | 4000 | B2 |

| PZP11900A22 | 11900 | 3144 | 2230 | 3500 | 3000 | B3 |

| PZP13600A21 | 13600 | 3593 | 2071 | 5100 | 4000 | B3 |

| PZP15000A25 | 15000 | 3963 | 2501 | 3500 | 3000 | B3 |

| PZP15800A22 | 15800 | 4174 | 2230 | 4500 | 4000 | B3 |

| PZP19700A22 | 19700 | 5205 | 2230 | 5500 | 5000 | B3 |

| PZP19900A25 | 19900 | 5258 | 2501 | 4500 | 4000 | B3 |

| PZP24800A25 | 24800 | 6552 | 2501 | 5500 | 5000 | B3 |