Olive oil is very sensitive. Many factors affect the quality of your oil – like air, light, heat, water, sediment. These speed up the oxidation process, shortening the shelf life of olive oil. It also likes to soak up nearby fragrances and flavors, which alter its taste and smell.

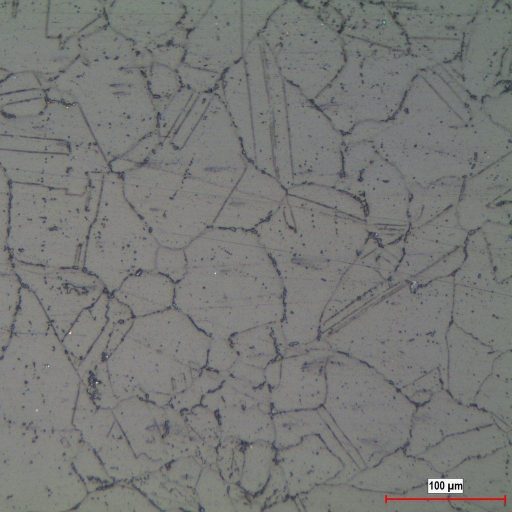

Stainless steel is the perfect material for olive oil storage. It has no flavor or odor, and is impenetrable by sun or moisture.

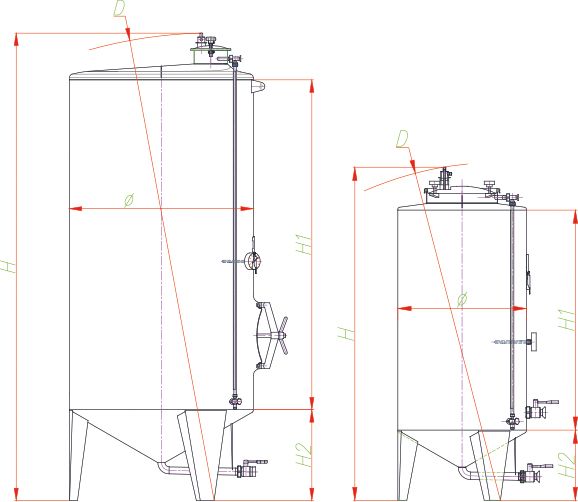

Letina [ZU] stainless steel tanks are designed specifically for olive oil storage and have several quality-of-life features aimed at the olive oil industry. Conical bottoms enable purging, special valves make racking easy, and the inert gas fitting prevents oxidation.

Durable, high-quality materials enable the olive oil storage tank to stay in pristine condition, even after years of professional usage.

![[Bottom] Conical Centered](https://letina.com/wp-content/uploads/tank-parts-bottoms-b6-conical-centered.jpg)

![[Bottom] Conical Centered](https://letina.com/wp-content/uploads/tank-parts-bottoms-b6-conical-centered.jpg)

![[Top] Conical Eccentric - Press Molded](https://letina.com/wp-content/uploads/tank-parts-tops-t1-conical-eccentric.jpg)

![[Top] Conical Eccentric - Press Molded](https://letina.com/wp-content/uploads/tank-parts-tops-t1-conical-eccentric.jpg)

| Type | Capacity (L) | Capacity (US gal) | Diameter (mm) | Total Height (mm) | Shell Height (mm) | Bottom | Top |

|---|---|---|---|---|---|---|---|

| ZU800A8 | 800 | 176 | 797 | 2299 | 1500 | B6 | T1 |

| ZU1000A8 | 1000 | 220 | 797 | 2799 | 2000 | B6 | T1 |

| ZU1250A8 | 1250 | 275 | 797 | 3299 | 2500 | B6 | T1 |

| ZU1500A8 | 1500 | 330 | 797 | 3799 | 3000 | B6 | T1 |

| ZU800A10 | 800 | 176 | 956 | 1810 | 1000 | B6 | T1 |

| ZU950A10 | 950 | 209 | 956 | 2060 | 1250 | B6 | T1 |

| ZU1050A10 | 1050 | 231 | 956 | 2210 | 1400 | B6 | T1 |

| ZU1150A10 | 1150 | 253 | 956 | 2310 | 1500 | B6 | T1 |

| ZU1500A10 | 1500 | 330 | 956 | 2810 | 2000 | B6 | T1 |

| ZU1850A10 | 1850 | 407 | 956 | 3310 | 2500 | B6 | T1 |

| ZU2200A10 | 2200 | 484 | 956 | 3810 | 3000 | B6 | T1 |

| ZU1350A11 | 1350 | 297 | 1116 | 2122 | 1250 | B6 | T1 |

| ZU1600A11 | 1600 | 352 | 1116 | 2372 | 1500 | B6 | T1 |

| ZU2050A11 | 2050 | 451 | 1116 | 2872 | 2000 | B6 | T1 |

| ZU2550A11 | 2550 | 561 | 1116 | 3372 | 2500 | B6 | T1 |

| ZU3050A11 | 3050 | 671 | 1116 | 3872 | 3000 | B6 | T1 |

| ZU4000A11 | 4000 | 880 | 1116 | 4872 | 4000 | B6 | T1 |

| ZU2100A13 | 2100 | 462 | 1275 | 2433 | 1500 | B6 | T1 |

| ZU2750A13 | 2750 | 605 | 1275 | 2933 | 2000 | B6 | T1 |

| ZU3350A13 | 3350 | 737 | 1275 | 3433 | 2500 | B6 | T1 |

| ZU4000A13 | 4000 | 880 | 1275 | 3933 | 3000 | B6 | T1 |

| ZU5300A13 | 5300 | 1166 | 1275 | 4933 | 4000 | B6 | T1 |

| ZU2550A14 | 2550 | 561 | 1402 | 2492 | 1500 | B6 | T1 |

| ZU3350A14 | 3350 | 737 | 1402 | 2992 | 2000 | B6 | T1 |

| ZU4100A14 | 4100 | 902 | 1402 | 3492 | 2500 | B6 | T1 |

| ZU4900A14 | 4900 | 1078 | 1402 | 3992 | 3000 | B6 | T1 |

| ZU6400A14 | 6400 | 1408 | 1402 | 4992 | 4000 | B6 | T1 |

| ZU4350A16 | 4350 | 957 | 1593 | 3056 | 2000 | B6 | T1 |

| ZU5350A16 | 5350 | 1177 | 1593 | 3556 | 2500 | B6 | T1 |

| ZU6350A16 | 6350 | 1397 | 1593 | 4056 | 3000 | B6 | T1 |

| ZU8350A16 | 8350 | 1837 | 1593 | 5056 | 4000 | B6 | T1 |

| ZU10350A16 | 10350 | 2277 | 1593 | 6056 | 5000 | B6 | T1 |

| ZU5350A18 | 5350 | 1177 | 1752 | 3106 | 2000 | B6 | T1 |

| ZU6550A18 | 6550 | 1441 | 1752 | 3606 | 2500 | B6 | T1 |

| ZU7750A18 | 7750 | 1705 | 1752 | 4106 | 3000 | B6 | T1 |

| ZU10150A18 | 10150 | 2233 | 1752 | 5106 | 4000 | B6 | T1 |

| ZU6400A19 | 6400 | 1408 | 1911 | 3229 | 2000 | B6 | T2 |

| ZU7850A19 | 7850 | 1727 | 1911 | 3729 | 2500 | B6 | T2 |

| ZU9250A19 | 9250 | 2035 | 1911 | 4229 | 3000 | B6 | T2 |