CIP (Clean-In-Place) STATION is a device that automates the cleaning of winery and brewery equipment without disassembling it. It consists of two or three tanks that store and heat the cleaning solutions and one or two pumps that circulate the solutions through the equipment, such as fermenters, brite tanks, and pipes. A spray ball is usually attached to the equipment to spray the solutions on the inner surfaces and remove any dirt, bacteria, or residues.

CIP machine can improve the hygiene, quality, and efficiency of the winemaking and brewing process, as it reduces the risk of contamination, saves time and labor, and optimizes the use of chemicals and water.

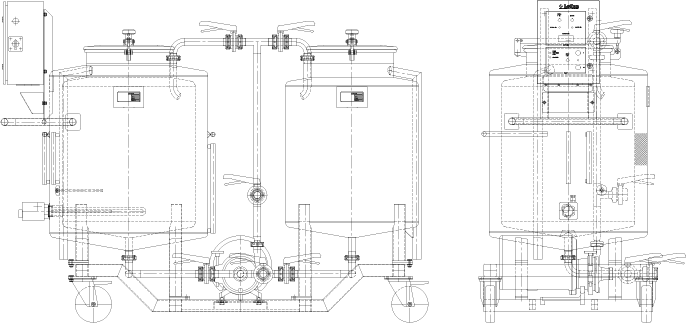

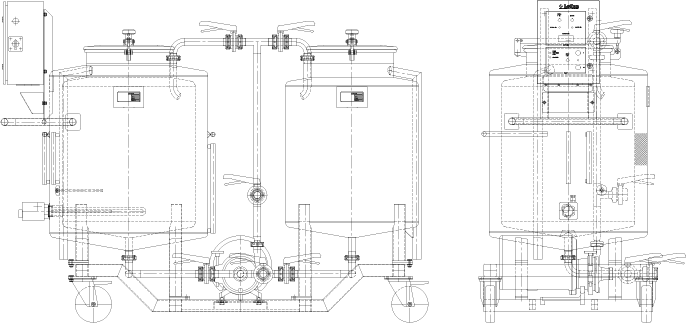

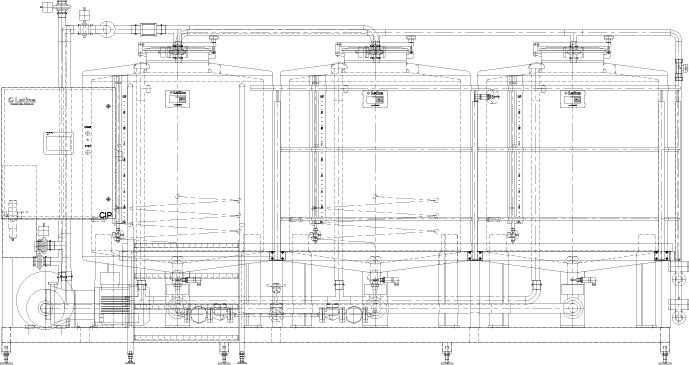

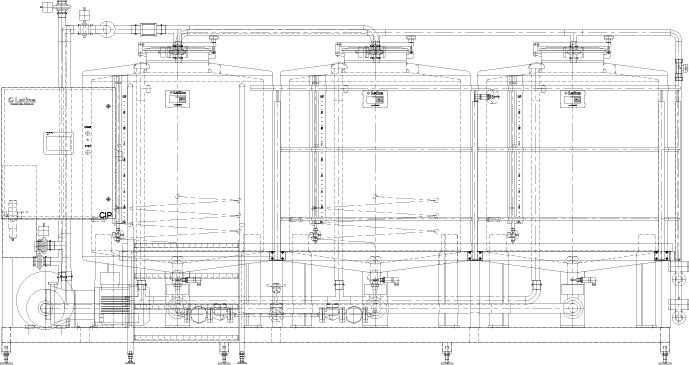

There are two types of CIP machines: two tanks CIP system and three tanks CIP system. The difference between them is the number of tanks that store the cleaning solutions.

| Type | Types of tanks | Volume per tank (L) | Volume per tank (US gal) | Pumps | Control | Valves | Construction |

|---|---|---|---|---|---|---|---|

| CIP 2x100 lit | alkaline + acid | 100 | 26 | 1 | manual | manual | mobile, on wheels |

| CIP 2x200 lit | alkaline + acid | 200 | 53 | 1 | manual | manual | mobile, on wheels |

| CIP 2x300 lit | alkaline + acid | 300 | 79 | 1 | manual | manual | mobile, on wheels |

| CIP 3x300 lit | alkaline + acid + water | 300 | 79 | 2 | automatic | electro-pneumatic | fixed, on frame |

| CIP 3x300 lit | alkaline + acid + water | 600 | 159 | 2 | automatic | electro-pneumatic | fixed, on frame |

| CIP 3x1000 lit | alkaline + acid + water | 1000 | 264 | 2 | automatic | electro-pneumatic | fixed, on frame |