The square tank was designed to better adapt to modern cellars. Thanks to its rectangular shape, it neatly fits into corners and along straight walls.

Placing the square tanks next to each other you gain cellar space that would otherwise be wasted due to the circular shape of other tanks.

Stack multiple square tanks on top of each other to make best use of all the available space.

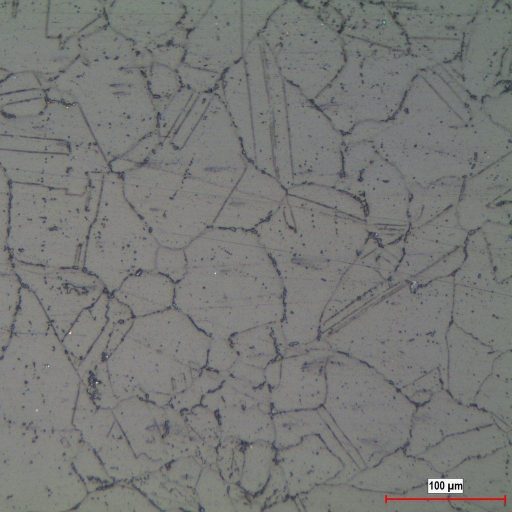

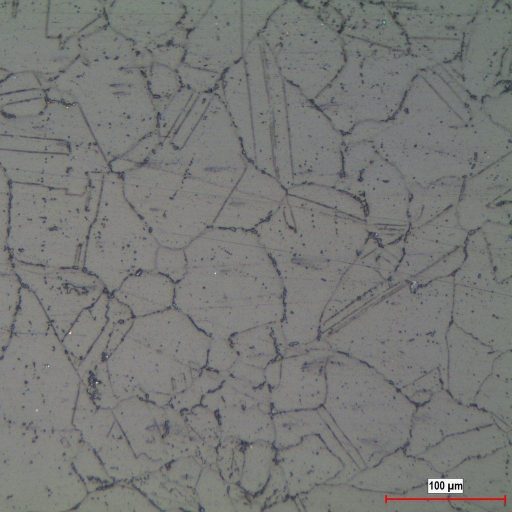

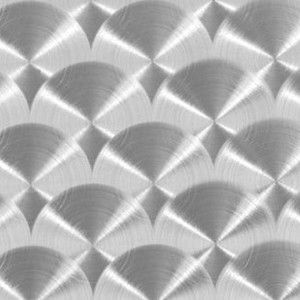

Durable, high-quality materials enable the tank to stay in pristine condition, even after years of professional usage.

Thanks to the vertical construction of the cooling jacket, the stored liquids will be efficiently chilled even if the tank is not full to the brim.

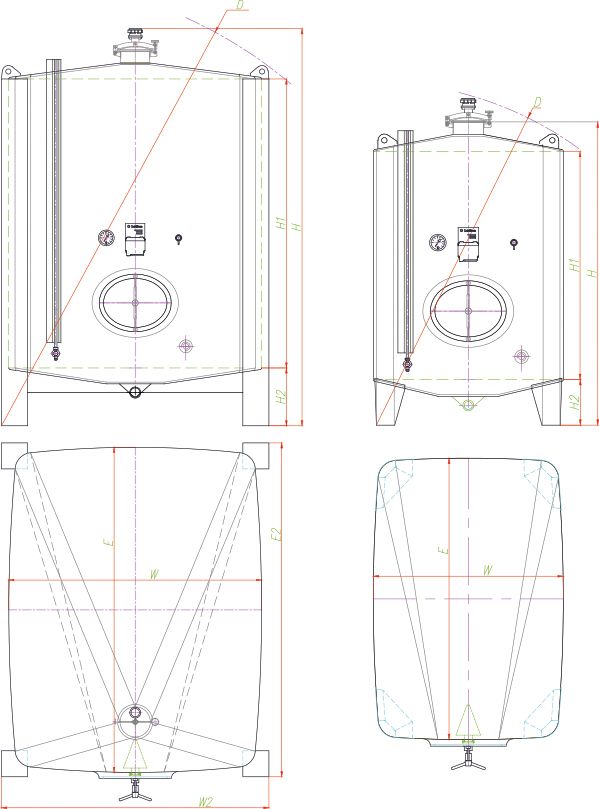

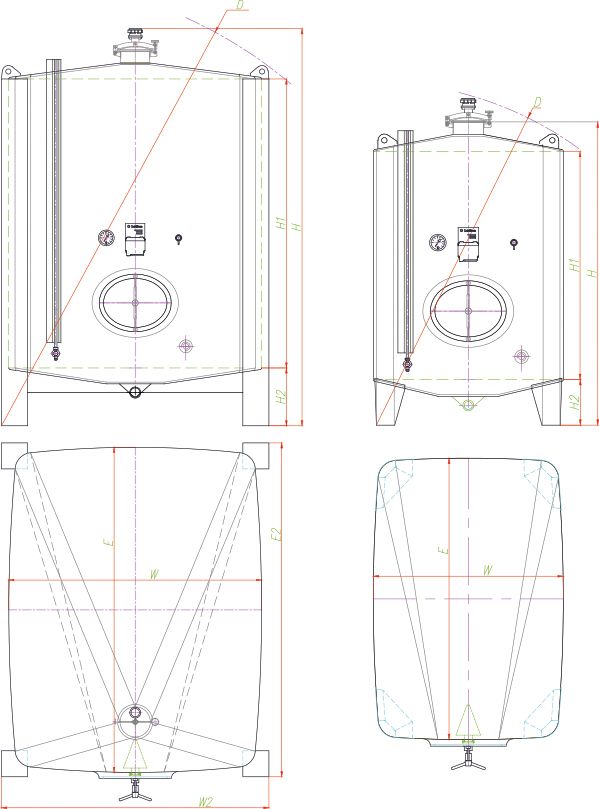

| Type | Capacity (L) | Capacity (US gal) | W1 (mm) | W2 (mm) | E1 (mm) | E2 (mm) | H1 (mm) | H2 (mm) | H (mm) | D (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| KR800A8-14 | 800 | 211 | 750 | - | 1350 | - | 750 | 300 | 1370 | 1400 |

| KR1000A8-14 | 1000 | 264 | 750 | - | 1350 | - | 1000 | 300 | 1620 | 1610 |

| KR1500A8-14 | 1500 | 396 | 750 | - | 1350 | - | 1500 | 300 | 2120 | 2140 |

| KR1650A10-17 | 1650 | 436 | 1000 | - | 1650 | - | 1000 | 300 | 1620 | 1690 |

| KR2000A8-14 | 2000 | 528 | 750 | - | 1350 | - | 2000 | 300 | 2620 | 2620 |

| KR2400A13-19 | 2400 | 634 | 1250 | - | 1850 | - | 1000 | 300 | 1650 | 1840 |

| KR2450A10-17 | 2450 | 647 | 1000 | - | 1650 | - | 1500 | 300 | 2120 | 2140 |

| KR3250A10-17 | 3250 | 859 | 1000 | - | 1650 | - | 2000 | 300 | 2620 | 2620 |

| KR3500A13-19 | 3500 | 925 | 1250 | - | 1850 | - | 1500 | 300 | 2150 | 2250 |

| KR4600A13-19 | 4600 | 1215 | 1250 | 1330 | 1850 | 1910 | 2000 | 300 | 2650 | 2730 |

| KR4650A15-21 | 4650 | 1229 | 1500 | 1600 | 2050 | 2110 | 1500 | 400 | 2250 | 2560 |

| KR6150A15-21 | 6150 | 1625 | 1500 | 1600 | 2050 | 2110 | 2000 | 400 | 2750 | 2950 |

| KR7650A15-21 | 7650 | 2021 | 1500 | 1600 | 2050 | 2110 | 2500 | 400 | 3250 | 3390 |

| KR7900A18-23 | 7900 | 2087 | 1750 | 1850 | 2250 | 2310 | 2000 | 400 | 2750 | 3100 |

| KR9800A18-23 | 9800 | 2589 | 1750 | 1850 | 2250 | 2310 | 2500 | 400 | 3250 | 3520 |

| KR11650A18-23 | 11650 | 3078 | 1750 | 1850 | 2250 | 2310 | 3000 | 400 | 3750 | 3950 |

| KR12150A20-25 | 12150 | 3210 | 2000 | 2100 | 2450 | 2530 | 2500 | 500 | 3350 | 3720 |

| KR14500A20-25 | 14500 | 3831 | 2000 | 2100 | 2450 | 2530 | 3000 | 500 | 3850 | 4160 |

| KR16900A20-25 | 16900 | 4465 | 2000 | 2100 | 2450 | 2530 | 3500 | 500 | 4350 | 4600 |

| KR17700A23-27 | 17700 | 4676 | 2250 | 2350 | 2650 | 2730 | 3000 | 500 | 3850 | 4300 |

| KR20550A23-27 | 20550 | 5429 | 2250 | 2350 | 2650 | 2730 | 3500 | 500 | 4350 | 4720 |

| KR23400A23-27 | 23400 | 6182 | 2250 | 2350 | 2650 | 2730 | 4000 | 500 | 4850 | 5150 |