Bag-in-tank serving tanks serve fresh beer and take up less space than a cold room and kegs. Eliminating the cold room reduces energy and chemical costs from keg cleaning. Bag in tank technology eliminates time and chemical expenses. Beer maintains high quality and freshness longer than using kegs. Tank is pressurized with air, no need for CO2 or other mixed gases to move beer to the taps. Using serving tanks helps reduce product loss and increase productivity and profit.

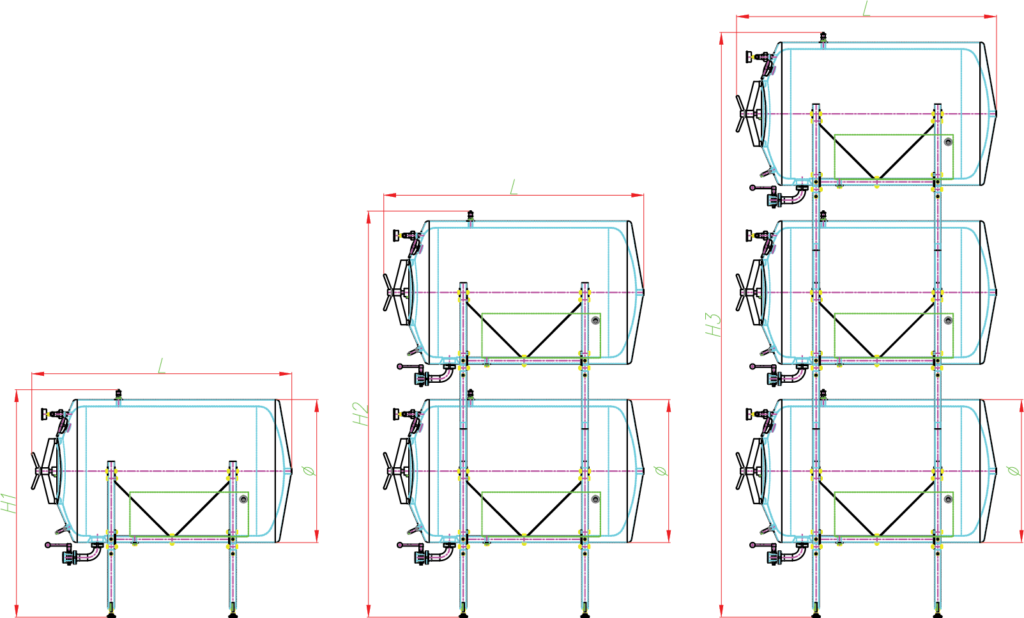

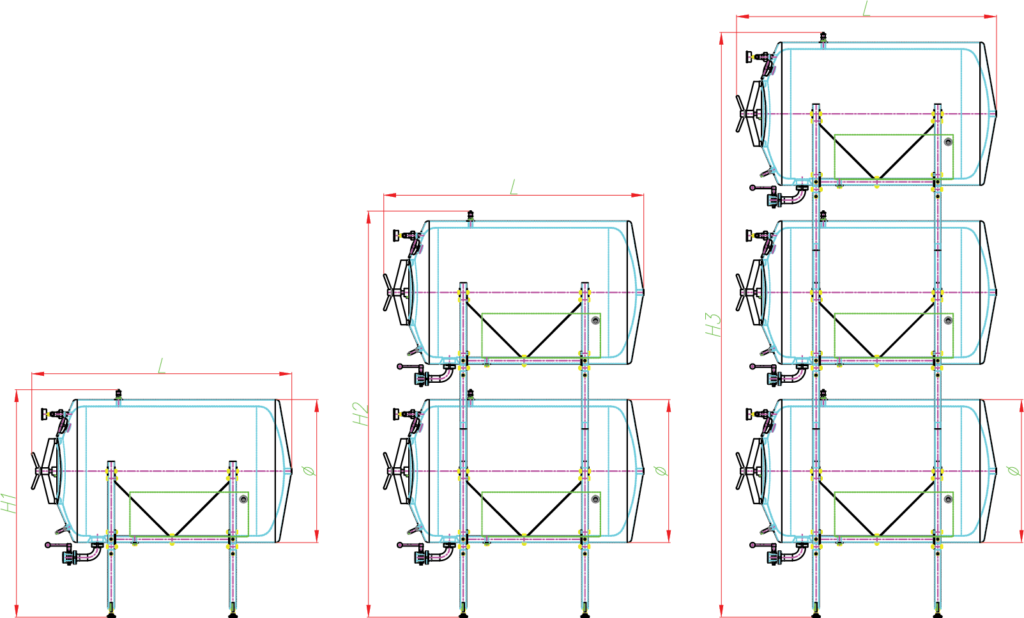

| Type | Capacity (L) | Total Volume (L) | Diameter (mm) | L (mm) | H1 (mm) | H2 (mm) | H3 (mm) |

|---|---|---|---|---|---|---|---|

| ZBS250A7 | 250 | 730 | 1240 | 1250 | 2275 | 3300 | |

| ZBS500A8 | 500 | 880 | 1600 | 1400 | 2500 | 3600 | |

| ZBS1000A8 | 1000 | 880 | 2560 | 1400 | 2500 | 3600 |

Bag-in-tank serving tanks save space, reduce costs, and keep beer fresher longer. They eliminate the need for a cold room and keg cleaning, lowering energy and chemical use. Plus, they use pressurized air instead of CO₂, reducing gas costs.

Horizontal tanks save space by allowing stacking, improve beer clarity by aiding yeast settling, and help maintain flavor stability. They’re great for efficient storage and high-quality brewing.

Letina’s system boosts productivity by reducing keg handling and cleaning time. It minimizes product loss and contamination, ensuring beer stays fresh. Plus, it cuts operational costs, increasing brewery profits.