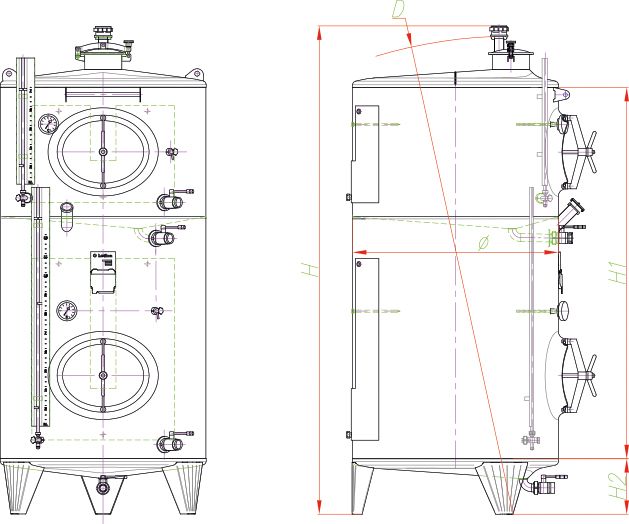

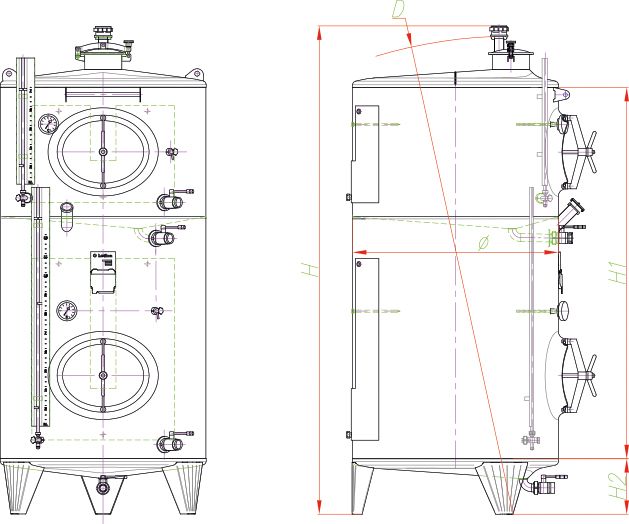

Designed to optimize the processing setup and maximize usable workspace, the multi-chamber tank offers multiple tanks in a single vessel.

Its chambers are completely separated allowing you to store different fluids with no fear of cross-contamination.

The tank can be used for fermentation and storage of wine and other alimentary liquids.

A large, dimpled jacket makes sure the temperature inside of the tank is always optimal. Thanks to the vertical construction of the cooling jacket, the stored liquids will be efficiently chilled even if the tank is not full to the brim.

Durable, high-quality materials enable the multi-chamber tank to stay in pristine condition, even after years of professional usage.

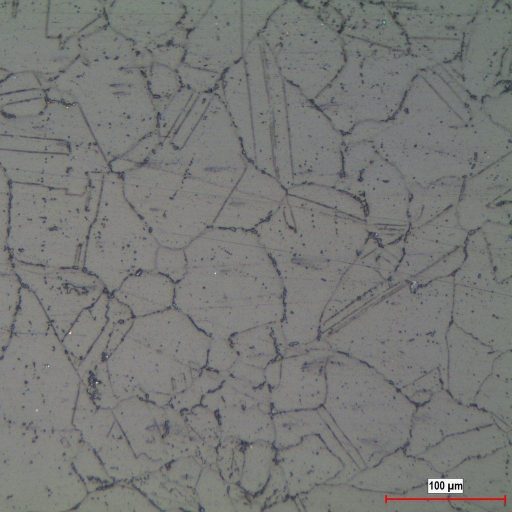

![[Bottom] Conical Eccentric - Press Molded](https://letina.com/wp-content/uploads/tank-parts-bottoms-b1-conical-eccentric.jpg)

![[Bottom] Conical Eccentric - Press Molded](https://letina.com/wp-content/uploads/tank-parts-bottoms-b1-conical-eccentric.jpg)

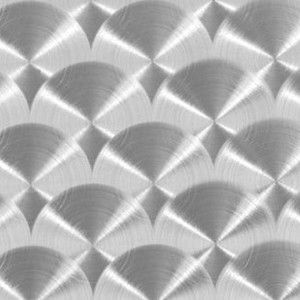

![[Top] Conical Eccentric - Press Molded](https://letina.com/wp-content/uploads/tank-parts-tops-t1-conical-eccentric.jpg)

![[Top] Conical Eccentric - Press Molded](https://letina.com/wp-content/uploads/tank-parts-tops-t1-conical-eccentric.jpg)

| Type | Capacity (L) | Capacity (US gal) | Diameter (mm) | Total Height (mm) | Shell Height (mm) | Bottom | Top |

|---|---|---|---|---|---|---|---|

| ZK500A8 | 500 | 132 | 797 | 1611 | 1000 | B1 | T1 |

| ZK600A8 | 600 | 159 | 797 | 1861 | 1250 | B1 | T1 |

| ZK750A8 | 750 | 198 | 797 | 2111 | 1500 | B1 | T1 |

| ZK750A10 | 750 | 198 | 956 | 1622 | 1000 | B1 | T1 |

| ZK900A10 | 900 | 238 | 956 | 1872 | 1250 | B1 | T1 |

| ZK1000A8 | 1000 | 264 | 797 | 2611 | 2000 | B1 | T1 |

| ZK1040A10 | 1040 | 275 | 956 | 2022 | 1400 | B1 | T1 |

| ZK1100A10 | 1100 | 291 | 956 | 2122 | 1500 | B1 | T1 |

| ZK1250A8 | 1250 | 330 | 797 | 3111 | 2500 | B1 | T1 |

| ZK1250A11 | 1250 | 330 | 1116 | 1884 | 1250 | B1 | T1 |

| ZK1450A10 | 1450 | 383 | 956 | 2622 | 2000 | B1 | T1 |

| ZK1500A8 | 1500 | 396 | 797 | 3611 | 3000 | B1 | T1 |

| ZK1500A11 | 1500 | 396 | 1116 | 2134 | 1500 | B1 | T1 |

| ZK1800A10 | 1800 | 476 | 956 | 3122 | 2500 | B1 | T1 |

| ZK2000A11 | 2000 | 528 | 1116 | 2634 | 2000 | B1 | T1 |

| ZK2000A13 | 2000 | 528 | 1275 | 2245 | 1500 | B1 | T1 |

| ZK2150A10 | 2150 | 568 | 956 | 3622 | 3000 | B1 | T1 |

| ZK2400A14 | 2400 | 634 | 1402 | 2250 | 1500 | B1 | T1 |

| ZK2450A11 | 2450 | 647 | 1116 | 3134 | 2500 | B1 | T1 |

| ZK2600A13 | 2600 | 687 | 1275 | 2745 | 2000 | B1 | T1 |

| ZK2950A11 | 2950 | 779 | 1116 | 3634 | 3000 | B1 | T1 |

| ZK3200A14 | 3200 | 845 | 1402 | 2750 | 2000 | B1 | T1 |

| ZK3250A13 | 3250 | 859 | 1275 | 3245 | 2500 | B1 | T1 |

| ZK3900A13 | 3900 | 1030 | 1275 | 3745 | 3000 | B1 | T1 |

| ZK3950A11 | 3950 | 1044 | 1116 | 4634 | 4000 | B1 | T1 |

| ZK3950A14 | 3950 | 1044 | 1402 | 3250 | 2500 | B1 | T1 |

| ZK4150A16 | 4150 | 1096 | 1593 | 2764 | 2000 | B1 | T1 |

| ZK4700A14 | 4700 | 1242 | 1402 | 3750 | 3000 | B1 | T1 |

| ZK5000A18 | 5000 | 1321 | 1752 | 2775 | 2000 | B1 | T1 |

| ZK5100A16 | 5100 | 1347 | 1593 | 3264 | 2500 | B1 | T1 |

| ZK5150A13 | 5150 | 1361 | 1275 | 4745 | 4000 | B1 | T1 |

| ZK6000A19 | 6000 | 1585 | 1911 | 2938 | 2000 | B2 | T2 |

| ZK6100A16 | 6100 | 1612 | 1593 | 3764 | 3000 | B1 | T1 |

| ZK6200A18 | 6200 | 1638 | 1752 | 3275 | 2500 | B1 | T1 |

| ZK6250A14 | 6250 | 1651 | 1402 | 4750 | 4000 | B1 | T1 |

| ZK7450A18 | 7450 | 1968 | 1752 | 3775 | 3000 | B1 | T1 |

| ZK7450A19 | 7450 | 1968 | 1911 | 3438 | 2500 | B2 | T2 |

| ZK8100A16 | 8100 | 2140 | 1593 | 4764 | 4000 | B1 | T1 |

| ZK8750A21 | 8750 | 2312 | 2071 | 3455 | 2500 | B3 | T2 |

| ZK8850A19 | 8850 | 2338 | 1911 | 3938 | 3000 | B2 | T2 |

| ZK9850A18 | 9850 | 2602 | 1752 | 4775 | 4000 | B1 | T1 |

| ZK10100A16 | 10100 | 2668 | 1593 | 5764 | 5000 | B1 | T1 |

| ZK10200A22 | 10200 | 2695 | 2230 | 3473 | 2500 | B3 | T2 |

| ZK10400A21 | 10400 | 2748 | 2071 | 3955 | 3000 | B3 | T2 |

| ZK11700A19 | 11700 | 3091 | 1911 | 4938 | 4000 | B2 | T2 |

| ZK12200A18 | 12200 | 3223 | 1752 | 5775 | 5000 | B1 | T1 |

| ZK12200A22 | 12200 | 3223 | 2230 | 3973 | 3000 | B3 | T2 |

| ZK13800A21 | 13800 | 3646 | 2071 | 4955 | 4000 | B3 | T2 |

| ZK14600A19 | 14600 | 3857 | 1911 | 5938 | 5000 | B2 | T2 |

| ZK15300A25 | 15300 | 4042 | 2501 | 4002 | 3000 | B3 | T2 |

| ZK16100A22 | 16100 | 4254 | 2230 | 4973 | 4000 | B3 | T2 |

| ZK17100A21 | 17100 | 4518 | 2071 | 5955 | 5000 | B3 | T2 |

| ZK20000A22 | 20000 | 5284 | 2230 | 5973 | 5000 | B3 | T2 |

| ZK20200A25 | 20200 | 5337 | 2501 | 5002 | 4000 | B3 | T2 |

| ZK20500A21 | 20500 | 5416 | 2071 | 6955 | 6000 | B3 | T2 |

| ZK23900A22 | 23900 | 6314 | 2230 | 6973 | 6000 | B3 | T2 |

| ZK25100A25 | 25100 | 6631 | 2501 | 6002 | 5000 | B3 | T2 |

| ZK30000A25 | 30000 | 7926 | 2501 | 7002 | 6000 | B3 | T2 |

| ZK34900A25 | 34900 | 9221 | 2501 | 8002 | 7000 | B3 | T2 |

| ZK39800A25 | 39800 | 10515 | 2501 | 9002 | 8000 | B3 | T2 |