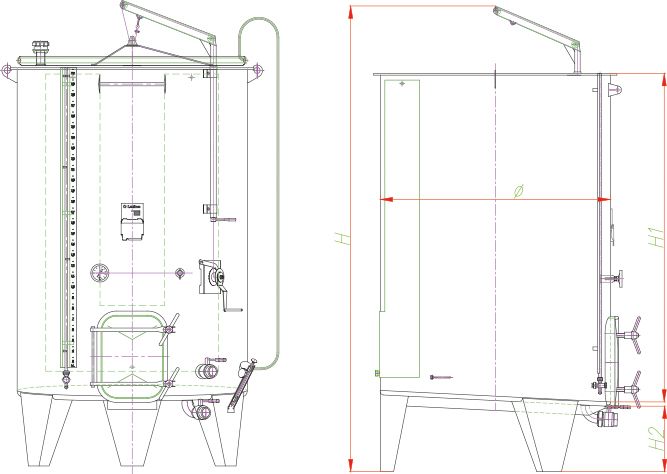

Designed for processing red wine, the PZPK variable capacity tank comes standard with a sloped bottom and a big square door. It is intended for professional use.

Durable, high-quality materials enable the variable capacity tank to stay in pristine condition, even after years of professional usage.

Thanks to the vertical construction of the cooling jacket, the stored liquids will be efficiently chilled even if the tank is not full to the brim.

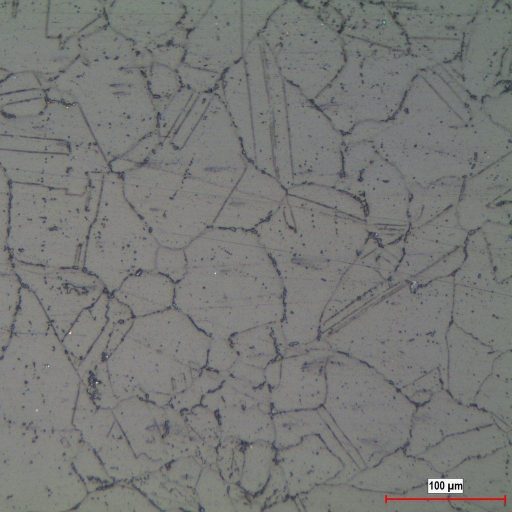

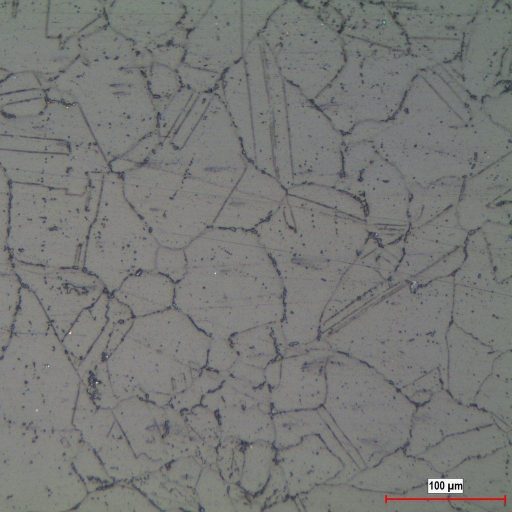

![[Bottom] Sloped](https://letina.com/wp-content/uploads/tank-parts-bottoms-b4-sloped.jpg)

![[Bottom] Sloped](https://letina.com/wp-content/uploads/tank-parts-bottoms-b4-sloped.jpg)

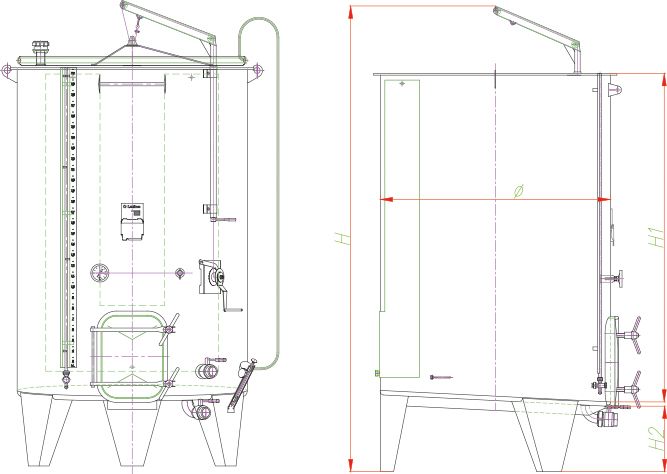

| Type | Capacity (L) | Capacity (US gal) | Diameter (mm) | Total Height (mm) | Shell Height (mm) | Bottom |

|---|---|---|---|---|---|---|

| PZPK300A6 | 300 | 79 | 638 | 1300 * | 1000 | B4 |

| PZPK390A6 | 390 | 103 | 638 | 1550 * | 1250 | B4 |

| PZPK410A7 | 410 | 108 | 731 | 1300 * | 1000 | B4 |

| PZPK470A6 | 470 | 124 | 638 | 1800 * | 1500 | B4 |

| PZPK490A8 | 500 | 132 | 797 | 1300 * | 1000 | B4 |

| PZPK510A7 | 510 | 135 | 731 | 1550 * | 1250 | B4 |

| PZPK620A7 | 620 | 164 | 731 | 1800 * | 1500 | B4 |

| PZPK610A8 | 630 | 166 | 797 | 1550 * | 1250 | B4 |

| PZPK730A8 | 750 | 198 | 797 | 1800 * | 1500 | B4 |

| PZPK880A10 | 880 | 232 | 956 | 1550 * | 1250 | B4 |

| PZPK1050A10 | 1050 | 277 | 956 | 2150 | 1500 | B4 |

| PZPK1150A11 | 1150 | 304 | 1116 | 1550 | 1250 | B4 |

| PZPK1400A10 | 1400 | 370 | 956 | 2650 | 2000 | B4 |

| PZPK1400A11 | 1400 | 370 | 1116 | 2220 | 1500 | B4 |

| PZPK1850A13 | 1850 | 489 | 1275 | 2350 | 1500 | B4 |

| PZPK1900A11 | 1900 | 502 | 1116 | 2700 | 2000 | B4 |

| PZPK2250A14 | 2250 | 594 | 1402 | 2350 | 1500 | B4 |

| PZPK2500A13 | 2500 | 661 | 1275 | 2850 | 2000 | B4 |

| PZPK3050A14 | 3050 | 806 | 1402 | 2850 | 2000 | B4 |

| PZPK3150A13 | 3150 | 832 | 1275 | 3350 | 2500 | B4 |

| PZPK3800A14 | 3800 | 1004 | 1402 | 3350 | 2500 | B4 |

| PZPK3950A16 | 3950 | 1044 | 1593 | 2900 | 2000 | B4 |

| PZPK4750A18 | 4750 | 1255 | 1752 | 2950 | 2000 | B4 |

| PZPK4900A16 | 4900 | 1295 | 1593 | 3400 | 2500 | B4 |

| PZPK5900A16 | 5900 | 1559 | 1593 | 3900 | 3000 | B4 |

| PZPK5950A18 | 5950 | 1572 | 1752 | 3450 | 2500 | B4 |

| PZPK7050A19 | 7050 | 1863 | 1911 | 3600 | 2500 | B4 |

| PZPK7150A18 | 7150 | 1889 | 1752 | 3950 | 3000 | B4 |

| PZPK8250A21 | 8250 | 2180 | 2071 | 3600 | 2500 | B4 |

| PZPK8500A19 | 8500 | 2246 | 1911 | 4100 | 3000 | B4 |

| PZPK9950A21 | 9950 | 2629 | 2071 | 4100 | 3000 | B4 |

| PZPK11300A19 | 11300 | 2985 | 1911 | 5100 | 4000 | B4 |

| PZPK11500A22 | 11500 | 3038 | 2230 | 3500 * | 3000 | B4 |

| PZPK13300A21 | 13300 | 3514 | 2071 | 5100 | 4000 | B4 |

| PZPK144000A25 | 14400 | 3804 | 2501 | 3500 * | 3000 | B4 |

| PZPK15400A22 | 15400 | 4069 | 2230 | 4500 * | 4000 | B4 |

| PZPK19300A22 | 19300 | 5099 | 2230 | 5500 * | 5000 | B4 |

| PZPK19300A25 | 19300 | 5099 | 2501 | 4500 * | 4000 | B4 |

| PZPK24200A25 | 24200 | 6394 | 2501 | 5500 * | 5000 | B4 |