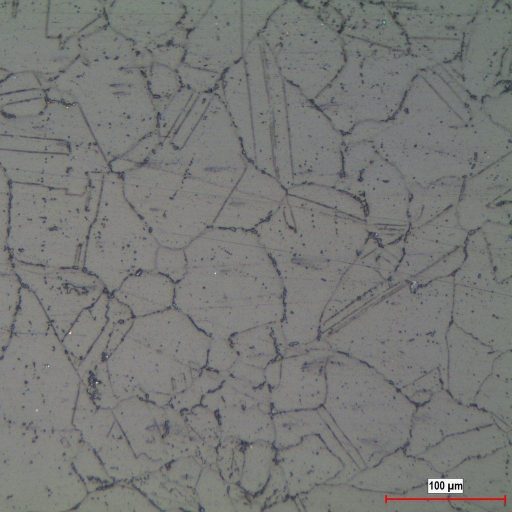

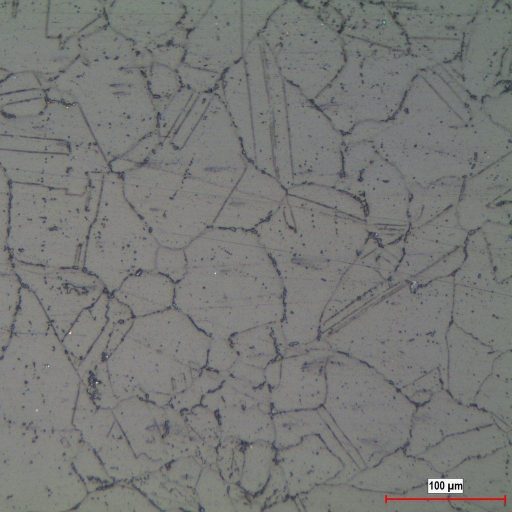

The conical fermenter is a vessel designed to produce high-quality craft beer. The conical fermenter can be used for fermentation, maturation and sedimentation.

What makes this beer fermentation tank special is its tall conical bottom. Thanks to its funnel shape, it separates and collects sediment. After the primary fermentation you can simply discharge the unwanted sediment, leaving the beer inside the tank.

![[Bottom] Conical Centered](https://letina.com/wp-content/uploads/tank-parts-bottoms-b6-conical-centered.jpg)

![[Bottom] Conical Centered](https://letina.com/wp-content/uploads/tank-parts-bottoms-b6-conical-centered.jpg)

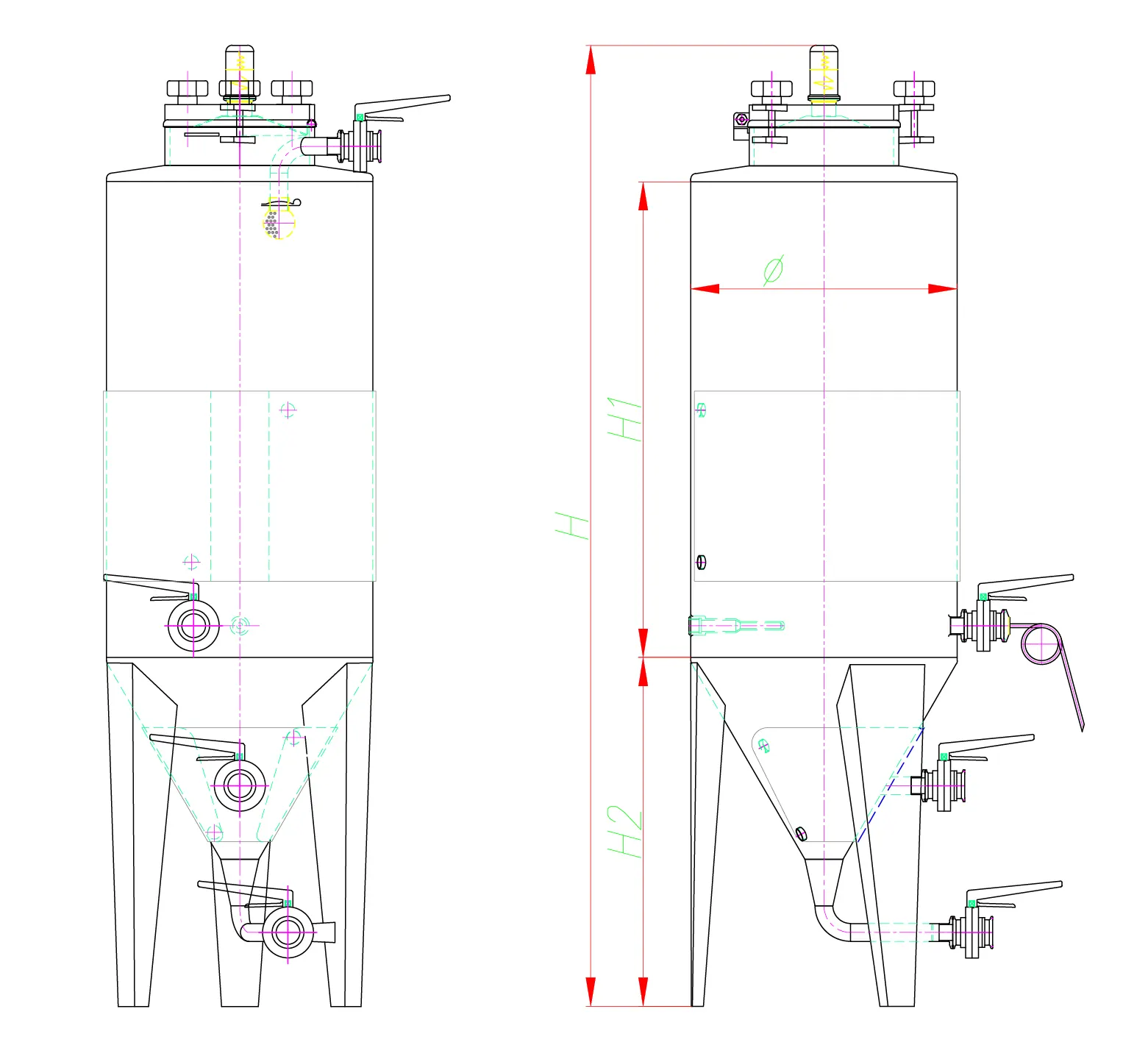

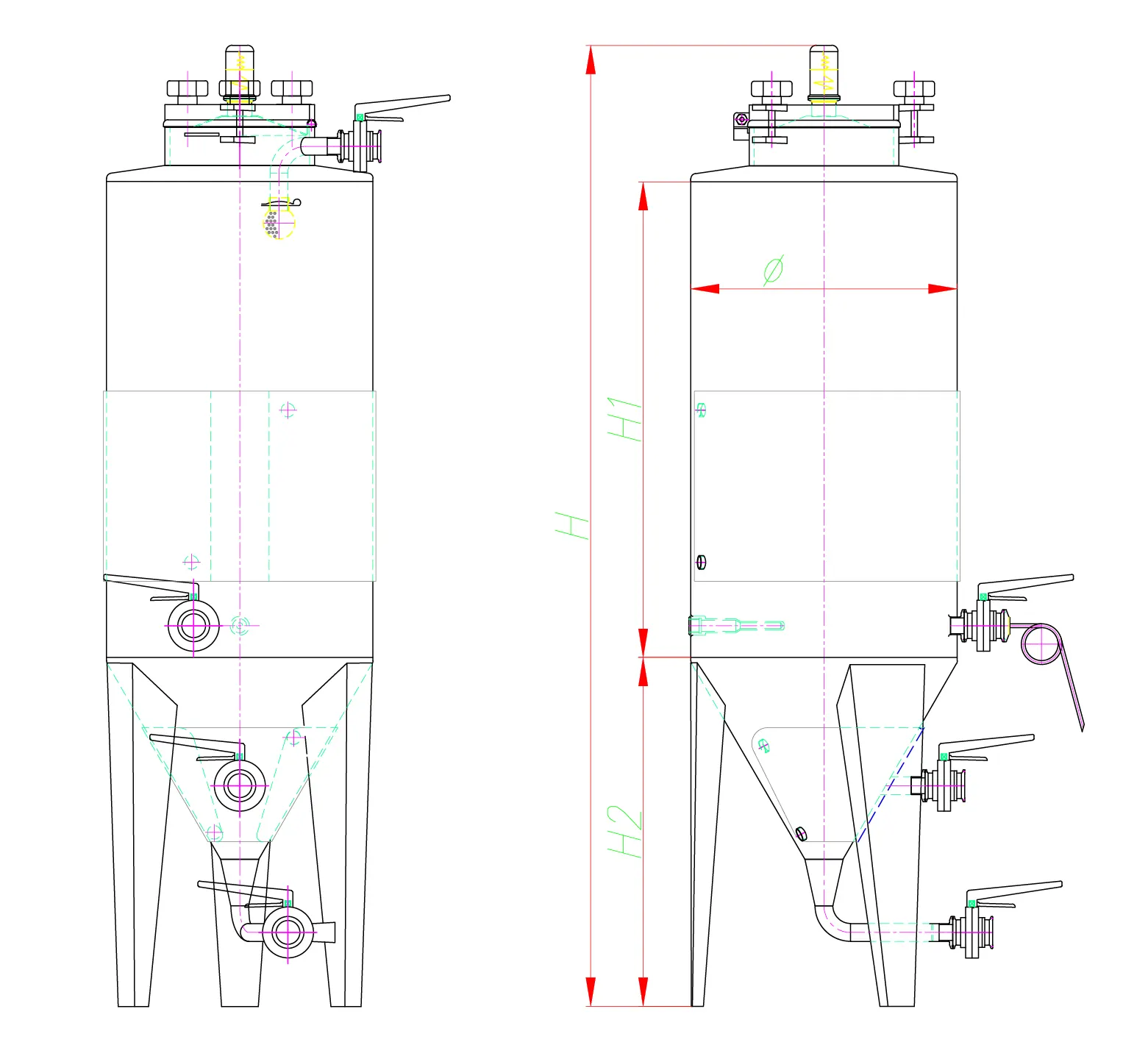

| Type | Capacity (L) | Capacity (US gal) | Total Volume (L) | Total Volume (US gal) | Diameter (mm) | H1 (mm) | H2 (mm) | H3 (mm) |

|---|---|---|---|---|---|---|---|---|

| ZBR50H4 | 50 | 13 | 70 | 18 | 420 | 400 | 550 | 1210 |

| ZBR100H4 | 100 | 26 | 120 | 32 | 420 | 750 | 550 | 1560 |

| ZBR150H5 | 150 | 40 | 180 | 48 | 510 | 750 | 600 | 1865 |

| ZBR200H5 | 200 | 53 | 230 | 61 | 510 | 1000 | 600 | 1865 |

| ZBR320H6 | 320 | 85 | 380 | 100 | 637 | 1000 | 700 | 1975 |

| ZBR400H6 | 400 | 106 | 460 | 122 | 637 | 1250 | 700 | 2225 |

| ZBR520H7 | 520 | 137 | 620 | 164 | 730 | 1250 | 800 | 2330 |

Conical fermenters are vessels designed specifically for the fermentation of beer. They feature a tall, funnel-shaped bottom that collects sediment during the fermentation process. Conical fermenters are fitted with a cooling solution and an insulation layer. They’re constructed out of thicker materials and reinforced at the welds to handle the higher pressures required for brewing beer.

Unitank is a term used to describe a vessel that can handle two-step fermentation by itself. Conical fermenters are often referred to as unitanks because they don’t need to transfer the product between primary and secondary fermentations.

There are plenty of reasons to use a conical fermenter and its tall, funnel-shaped bottom. It separates and collects sediment. After the primary fermentation, you can easily discharge the unwanted sediment without transferring the beer to another tank.

Doing two-step fermentation in a single tank has multiple benefits. Firstly, you save space (and money) from using a single tank instead of two. More importantly, you don’t need to risk contamination and oxidation of your product by eliminating transferring entirely. Lastly, they allow you to easily collect and reuse your yeast.

Simply put, conical fermenters help you make better beer, simplify brewing, and save you money in the process.

No more scrubbing – cleaning the beer fermentation tank is a breeze thanks to the clean in place system. Letina stainless steel conical fermenters come equipped with sanitary CIP pipes and effective spray balls.

The highly-polished stainless steel interior prevents sediment build-up and makes it easy to keep your conical fermenter hygienic and stain-free.